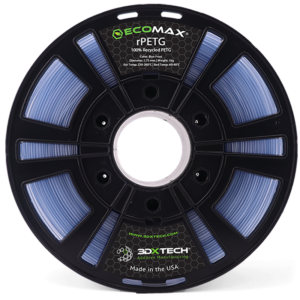

PETG 3D Printing Filament

MAX-G™ Premium PETG is made using premium copolyester resin. PETG is one of the best printing materials on the market with excellent layer bonding, low warp, no odor, improved chemical resistance, and brilliant color options.