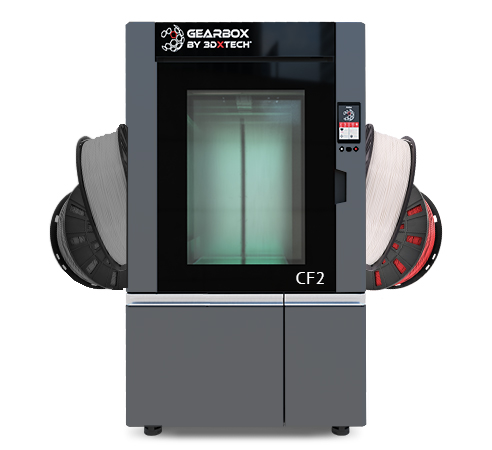

Gearbox CF2

High Performance 3D Printer

Introducing the next phase of Gearbox™ Printers

Schedule a Gearbox 3D printer demo, designed to discuss your specific 3D printing requirements at a time that fits your calendar.

Schedule a Demo

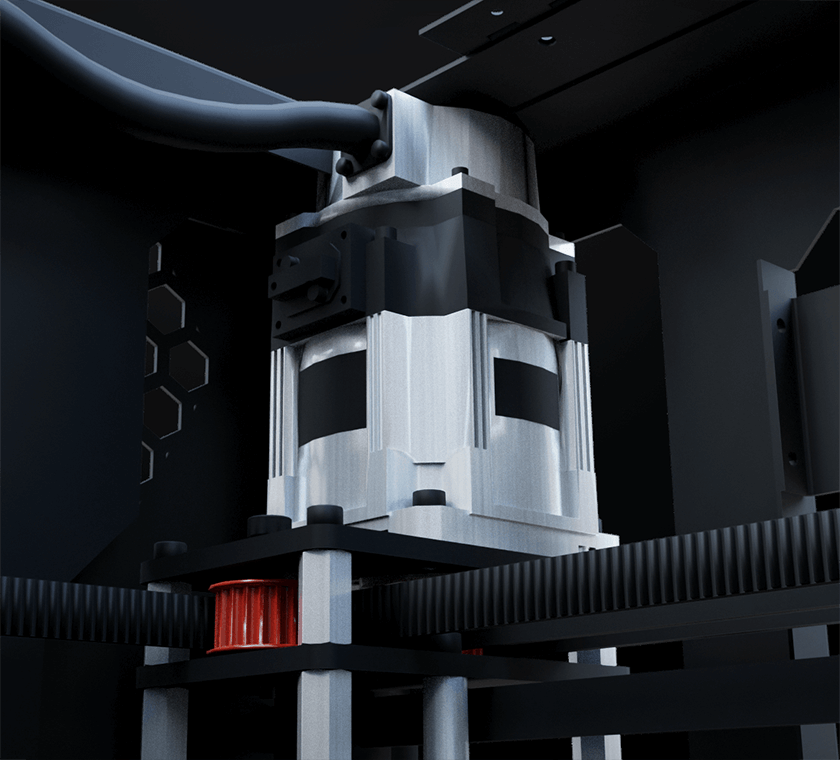

Designed to print to endure the abrasive nature of fiber engineered materials. The specialty hardened manufacturing process will keep your machine printing high quality parts regardless of the material used.

The Gearbox CF2 was created by people who understand both 3D printing and 3D filament. The CF2 was designed to print large scale, fast, and accurately all at once, without the ridiculous price tag of closed-source systems.

While you will have the entire 3DXTECH™ material library at your disposal we will never require you to use our materials. Creating quality 3D prints is our only priority.

Printing Technology: Fused Filament Fabrication [FFF]

Build Volume: 18″ x 18″ x 24″ [457mm x 457mm x 610mm]

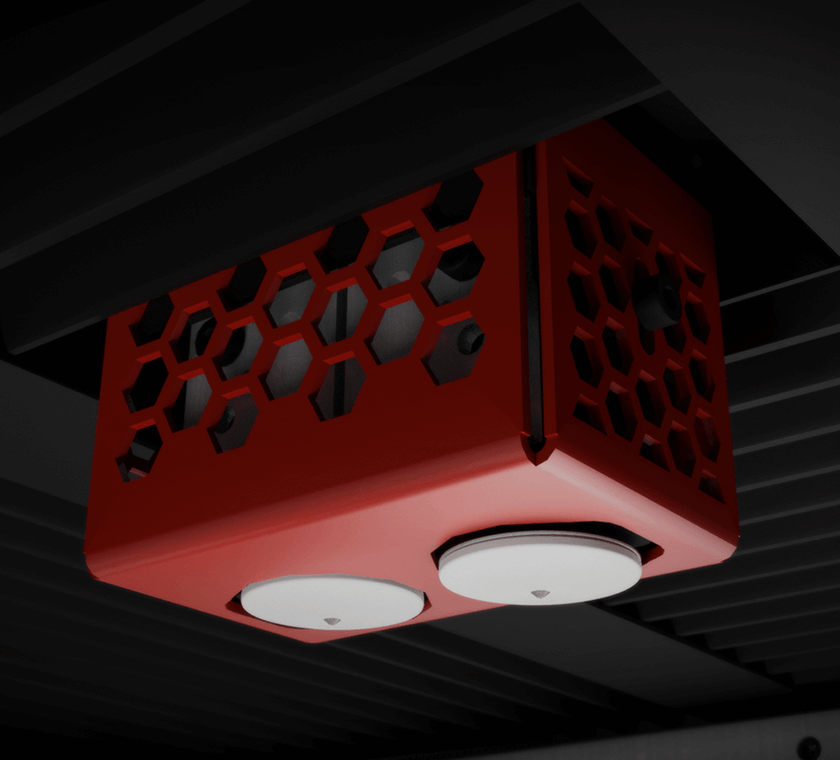

Heated Build Chamber: Up to 135ºC

Number of Extruders: 2 [Model & Support]

Extruder Temperature: Up to 500ºC

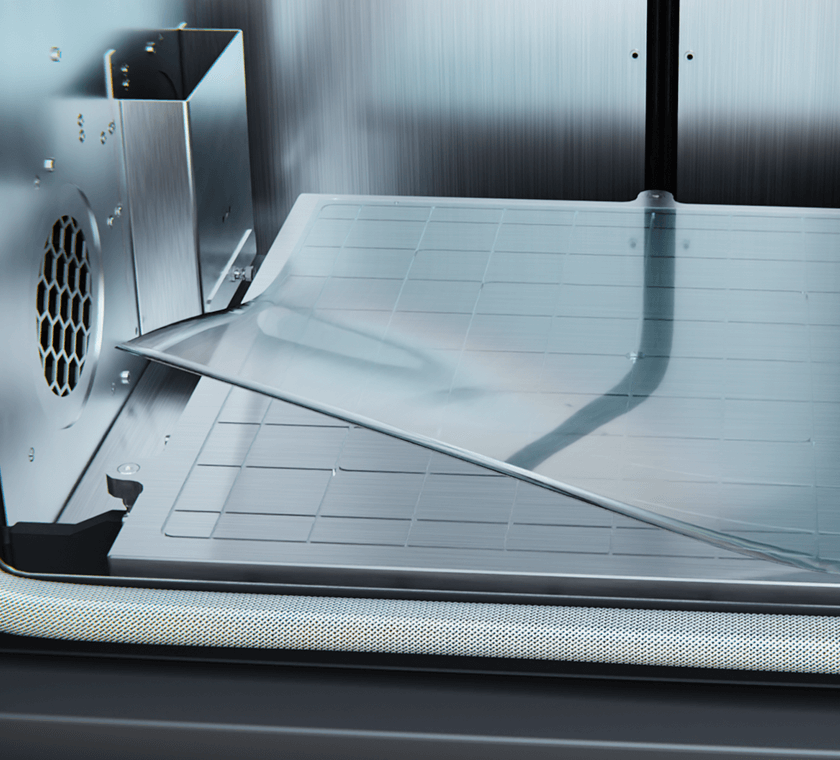

Print Bed Type: Vacuum Plate

Print Bed Surface: Removable Plastic Build Sheet

Filament Diameter: 1.75mm [Open Source]

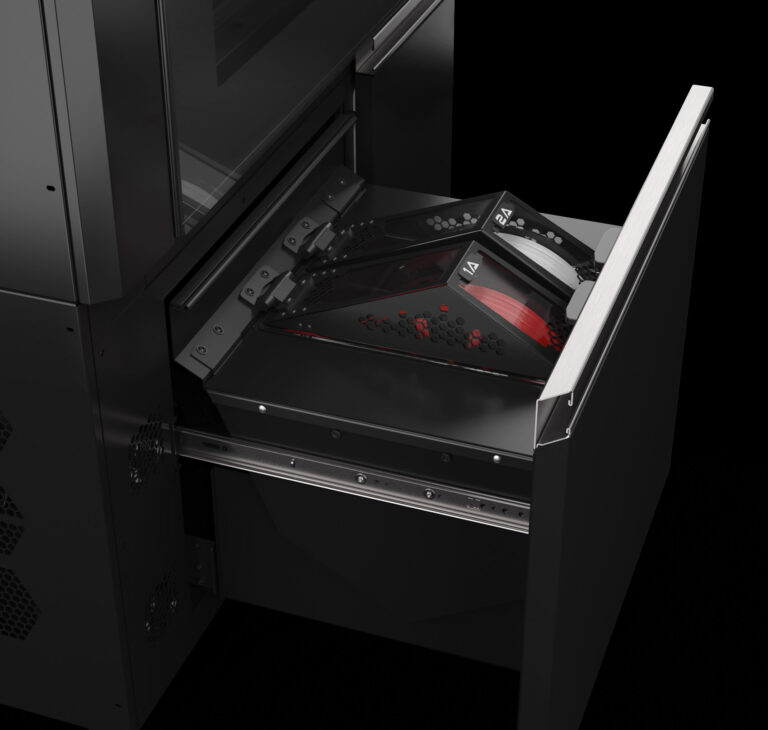

Onboard Filament Capacity: 8kg [2 x 4kg Reels]

Filament Storage: 2 Actively Dried Filament Bays

Unlimited Open Source Options

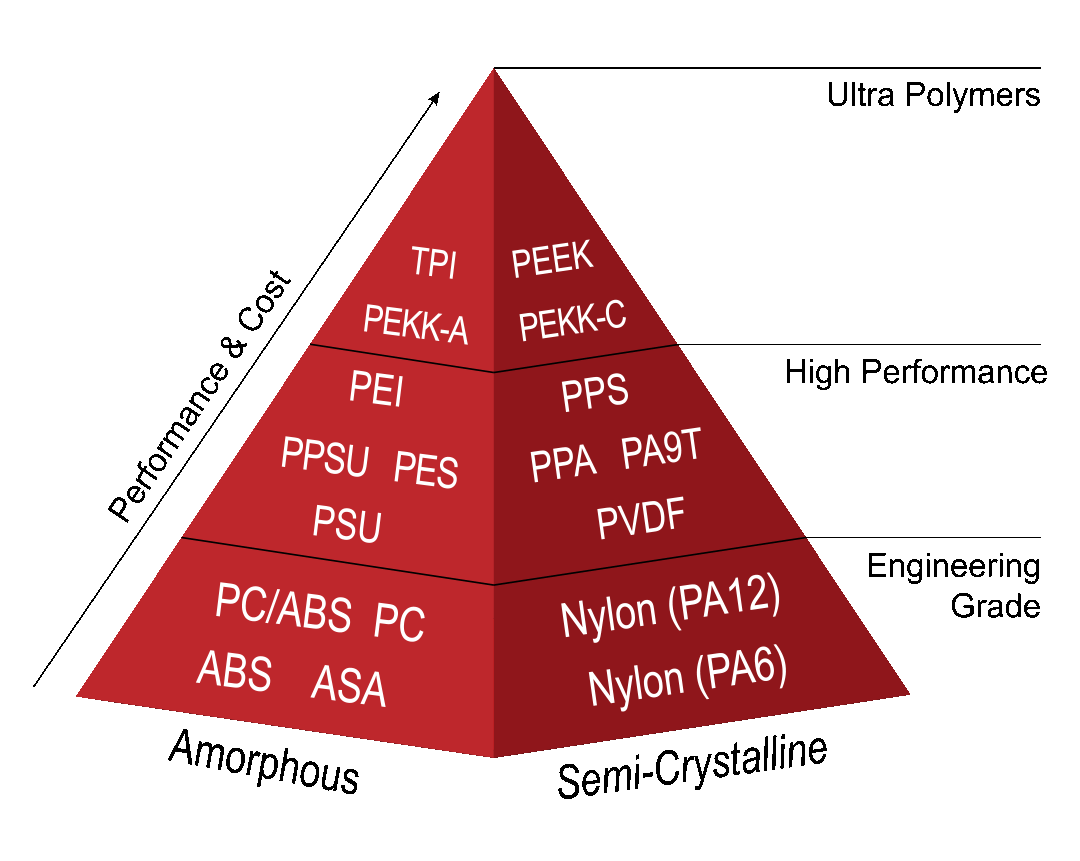

Specialty Grades: Carbon Fiber, Glass Fiber, ESD-Safe, Flame Retardant

Model Materials: HTN, PPS, PA12, PA6, PC, PC/ABS, ASA, ABS [Unlimited Open Source]

Support Grades: Water Soluble, Break Away Support

Print Speed: Up to 300mm/s

Nozzle Sizes: .25, .31, .36, .41, .51, .76, 1.02 mm

Resolution [Theoretical]: XY: ± .127 mm or ± .0015 mm/mm [Whichever is Greater]

Mechanical Actuation: High-Speed Servos (Yaskawa)

Bed Leveling: Automatic

Slicer: Gearbox3D Custom Slicer

Control Panel: 7″ Color Touch Screen

External Dimensions: 44.8″ x 36.1″ x 79″

Printer Weight: 1450 lbs [658 kg]

Power Requirements: 240 VAC, 1 Phase, 60 Hz, 50 Amps, NEMA 6-50 Plug Provided

Manufacturing Location: Grand Rapids, MI [USA]

Please fill out the form today to order your Gearbox™ CF2 and learn more information.