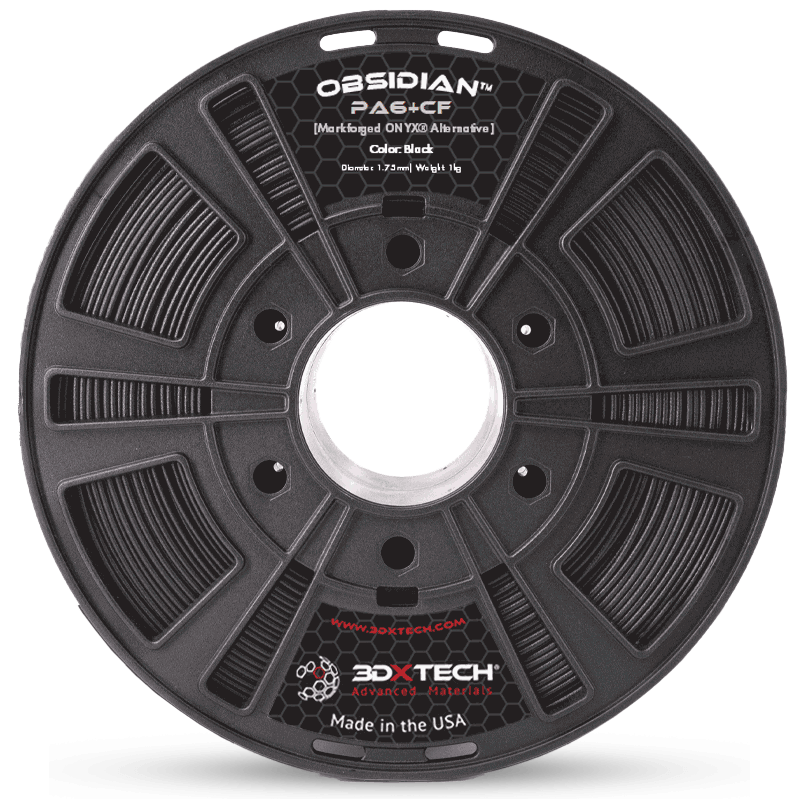

Obsidian™ PA6+CF is an excellent drop-in replacement for Markforged Onyx™ and is compatible for use in all Markforged printers.

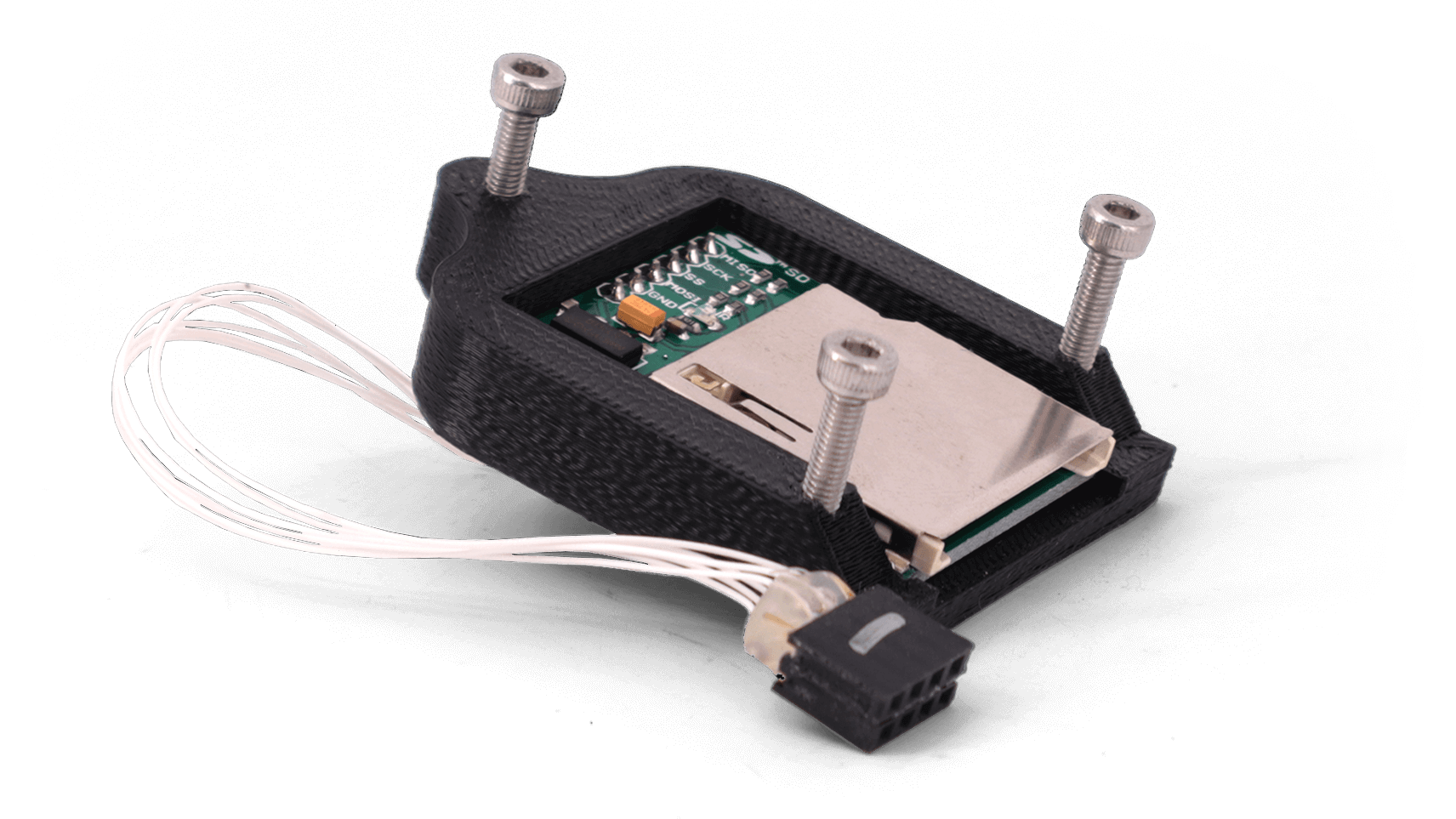

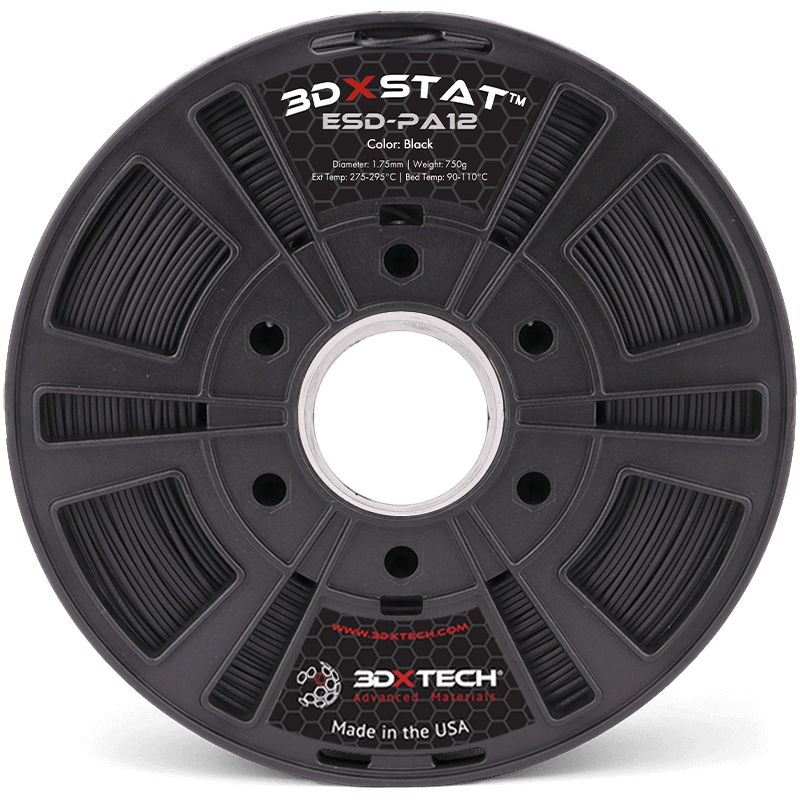

ESD-Safe 3D Printing Filaments

3DXTECH has the largest selection of ESD-Safe 3D printing filaments on the market. Customize your electronics housing!

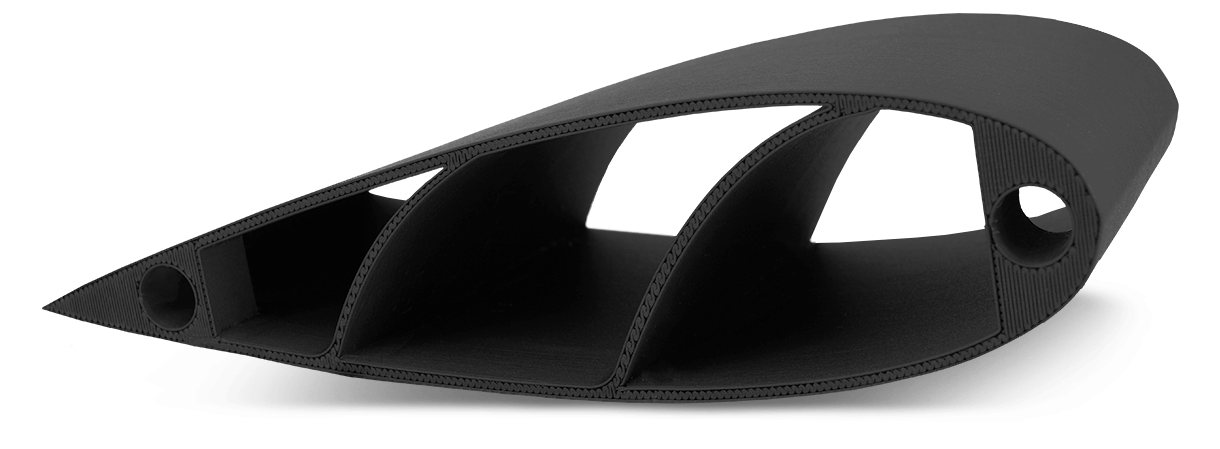

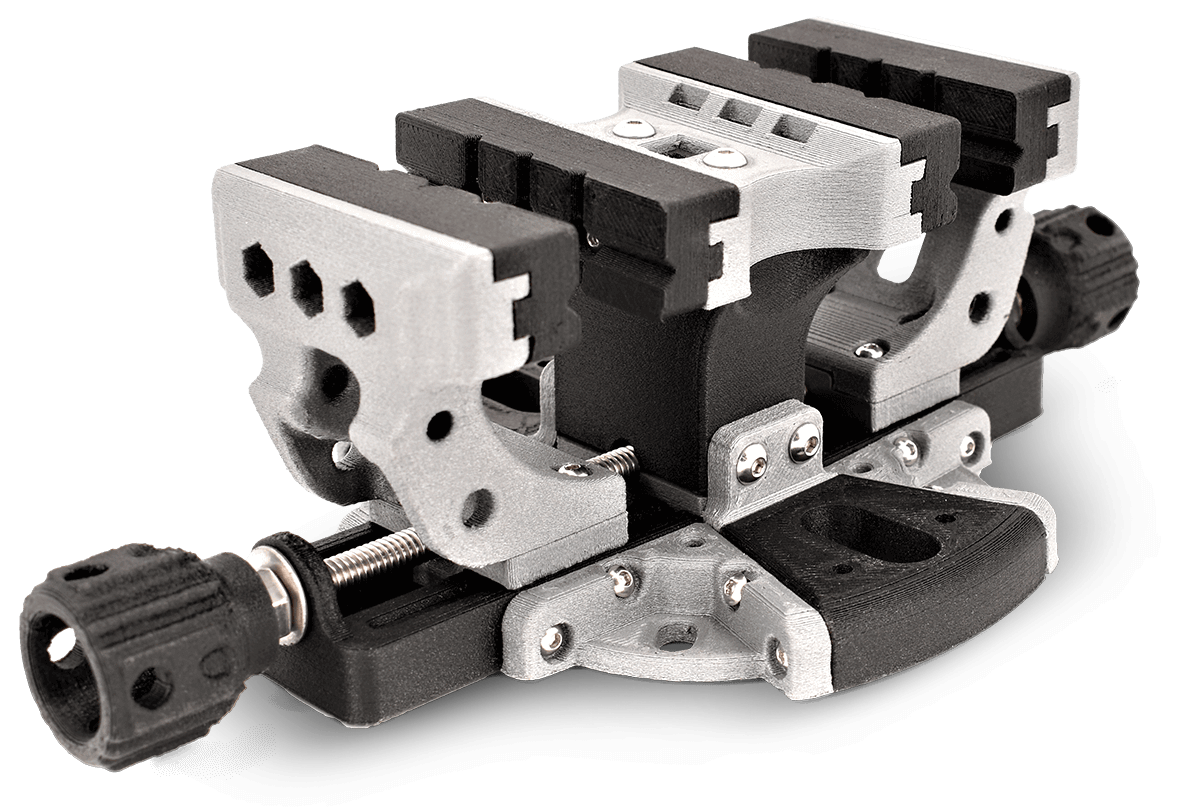

Carbon Fiber Reinforced 3D Printing Filaments

The largest selection of carbon fiber 3d printing filaments on (and above) planet Earth.

Stratasys® Compatible Materials

Now Available!

3DXTECH offers Stratasys Compatible Materials from Triton 3D.

Refill your Fortus & Dimension printers. Restock on Build Sheets and Tips made from hardened Steel!

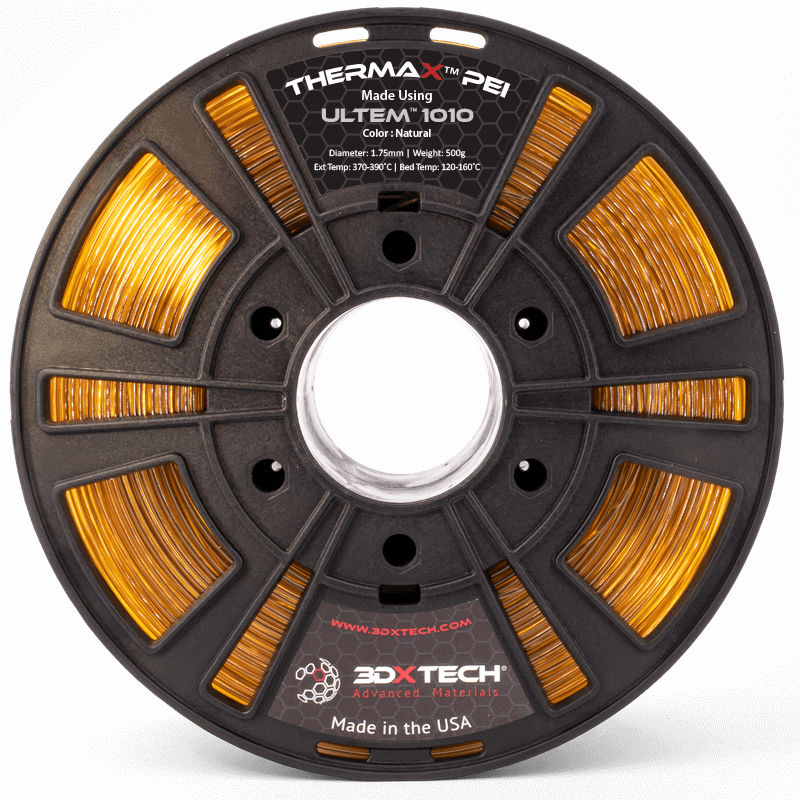

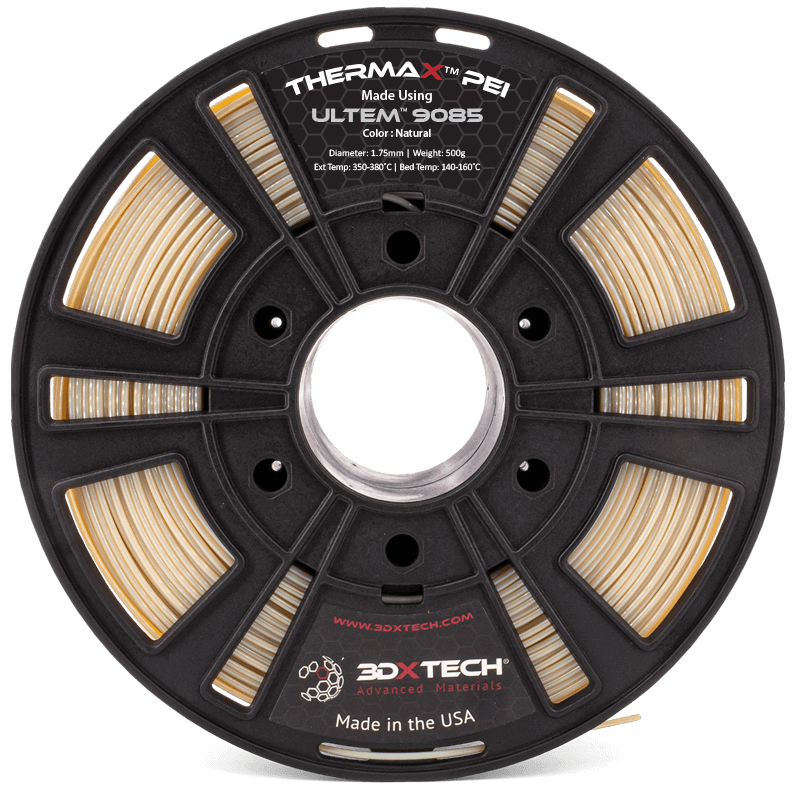

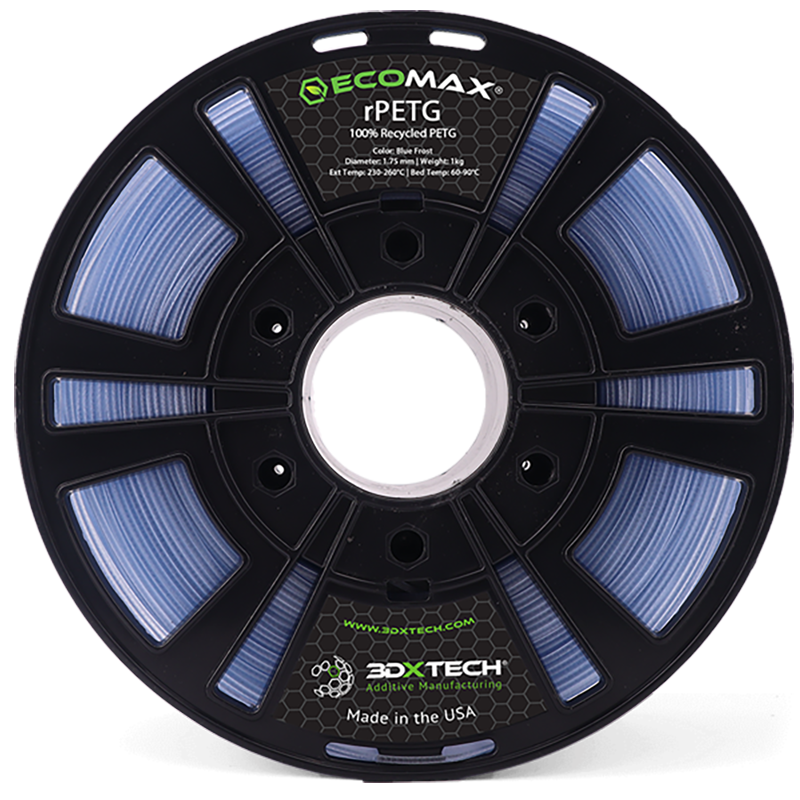

Featured 3D Filaments

New

ON SALE

ON SALE

3D Filament Specialties

New Products

New

Hot Seller!

The latest in 3D printers

Build more with the new Gearbox™ HT2 3D Printer

Gearbox 3D Printer Ht2 Brochure