Description

| ThermaX PEEK (PolyEtherEtherKetone) is one of the highest-performance polymers in world. In fact, it’s one of the highest-performance plastics ever invented. PEEK has exceptional mechanical, thermal, and chemical resistance properties making it a go-to material in some of the most demanding applications where failure is not an option. |

Benefits of ThermaX PEEK

- Inherently flame resistant and self-extinguishing

- Long-term hydrolytic stability even above 250C

- Outstanding resistance to a broad range of chemicals, including automotive fluids, fully halogenated hydrocarbons, alcohols, and aqueous solutions

- Low smoke and toxic gas emissions

- Excellent dimensional stability with low heat creep, low and uniform coefficient of thermal expansion, giving PEEK highly reproducible part-to-part dimensions

- High thermal properties with a Tg of 143C, CUT of 240-260C, and Tm of 343c

Reviews

Print Recommendations

Extruder Temp

375-410C

Bed Temp

130-145C

Heated Chamber

Recommended 70-140C if possible

Nozzle Specs

No special concerns

Layer Height

No special concerns

Drying Specs

120C for 4 hours

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently and the printer will experience extrusion issues.

Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

Material DETAILS

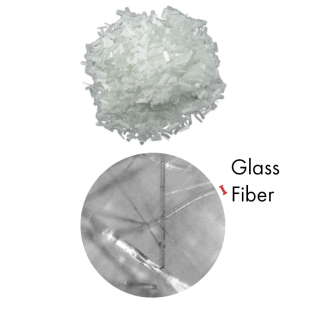

Glass Fiber Reinforced Filament

What Is It?

DescriptionFibers made of glass reinforced into the polymer during manufacturing and aligned along the axis of filament.

This, along with their physical makeup, give this material enormous strength and mechanical properties.

What Does It Do?

Glass fiber reinforcement gives material a lot of desirable properties:

High strength

High stiffness

High chemical resistance

Low thermal expansion

How Does It Work?

Reinforcing plastic with glass fibers produces a 3D printing filament which exhibits the best properties of both fiberglass and the plastic of choice.

What Is It Good For?

Ideal for any applications which require strength and rigidity.

For these reasons, glass fiber reinforced filament is very popular in automotive, mechanical, civil engineering, and research industries.

RECOMMENDED

You May Also Like

Make confident choices and discover the best printing solutions.