3D Printing Jigs, Fixtures, and Tooling

Increase productivity, save time, save money.

Utilizing additive manufacturing to create jigs, features, and tooling has the potential to produce significant savings in both time and cost. With additive manufacturing, you have the opportunity to avoid production delays when fixtures break and reduce the cost of materials and lead time.

Rapid Prototyping

Quick design iterations enable faster prototyping and testing, allowing for more efficient refinement of tools.

Customization

Additive manufacturing allows for highly customized designs tailored to specific manufacturing processes, improving ergonomics and efficiency.

Reduced Lead Times

Streamlined production processes cut down on lead times, enabling faster turnaround for manufacturing needs.

Lower Costs for Low Volumes

Additive manufacturing can be more cost-effective for small batches or one-off production compared to traditional tooling methods.

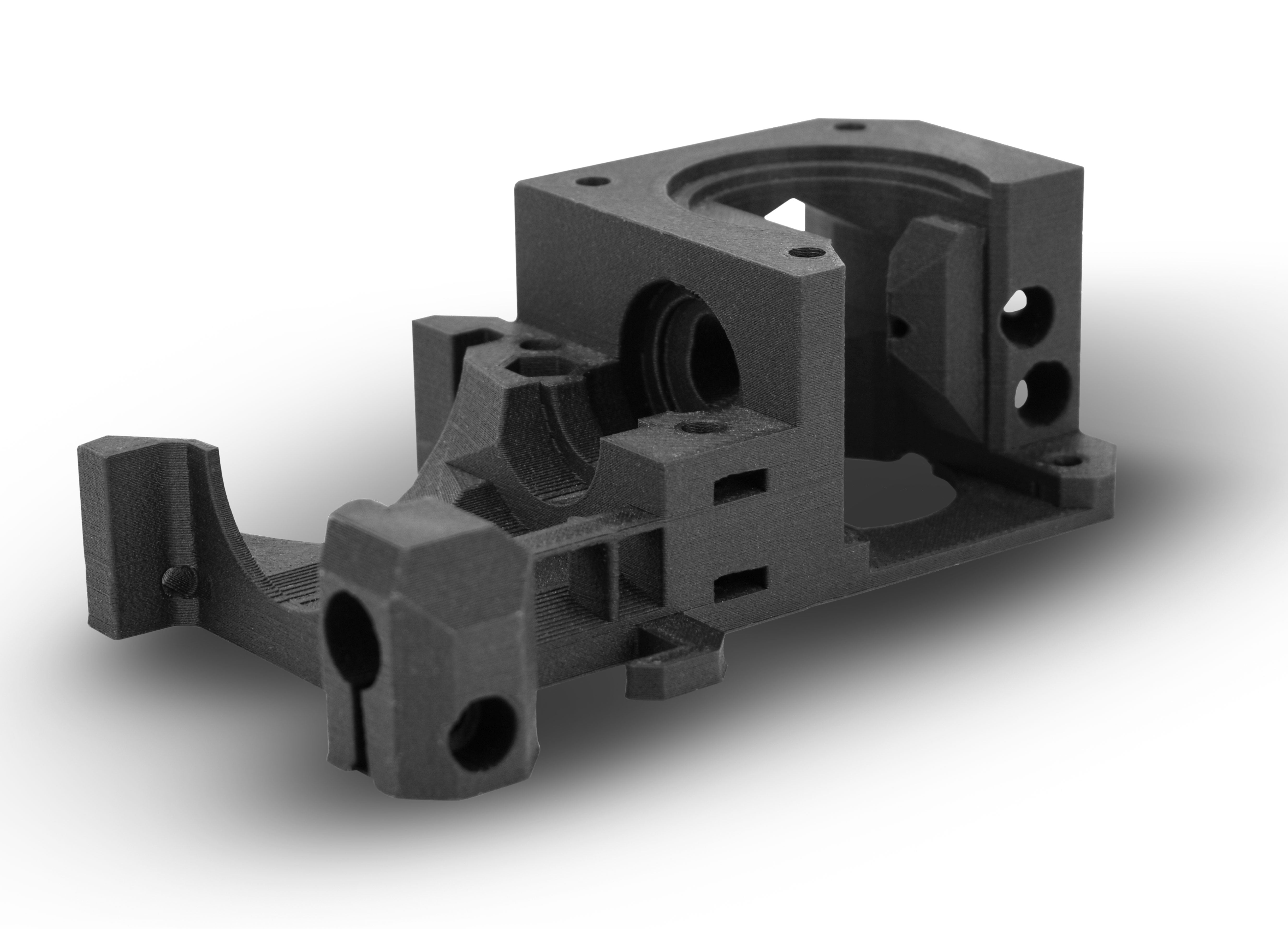

Popular Applications of Jigs, Fixtures, and Tooling

End of Arm Tooling

Assembly Fixtures

Composite Tooling

Brackets

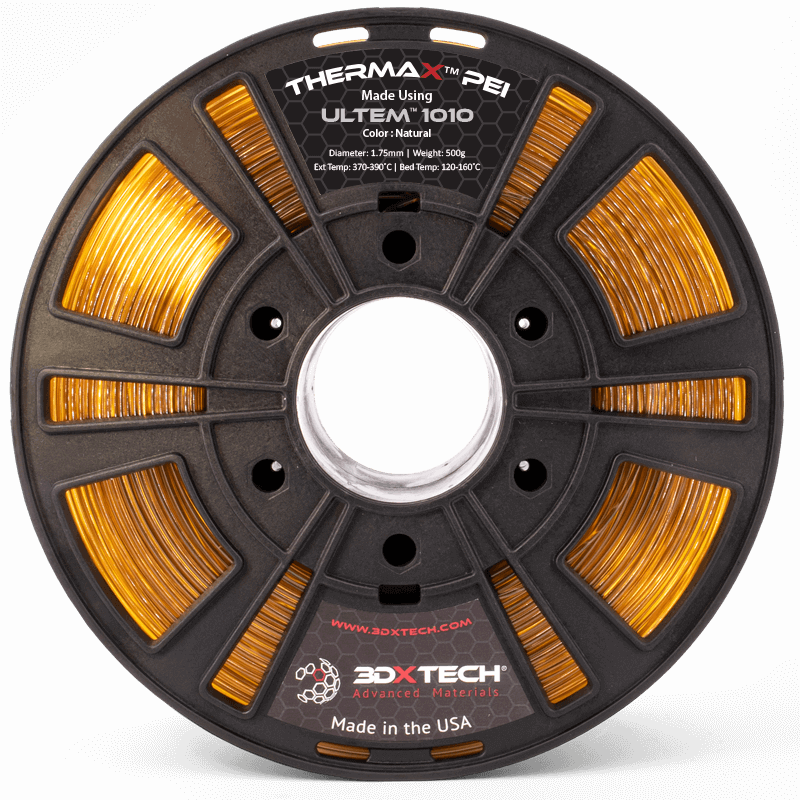

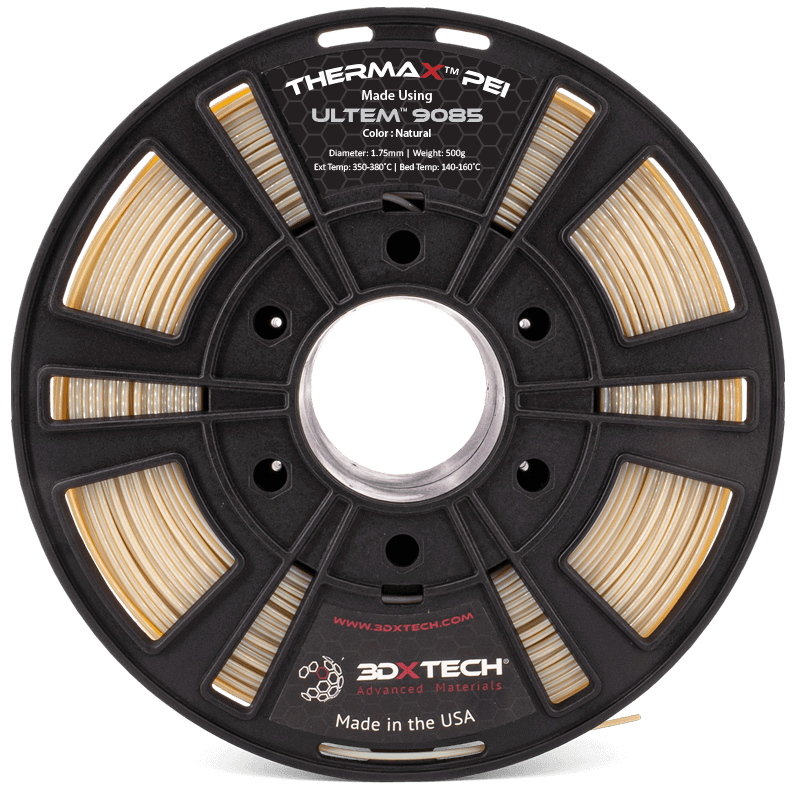

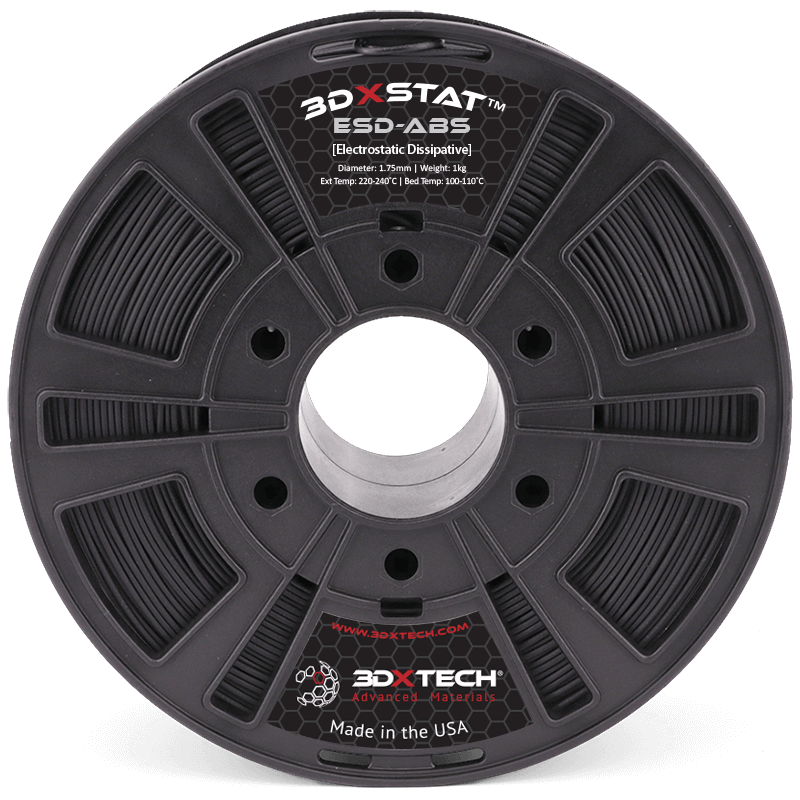

Popular Filaments used for Jigs, Fixtures, and Tooling

NEED STRATASYS COMPATIBLE FILAMENT?

Don't worry! We've got you covered.