Lightweighting with Advanced 3D Printing Filaments: Stronger, Lighter, Better

Lightweighting has become a driving force across industries where performance, efficiency, and durability matter most. From aerospace and automotive to defense and UAVs, engineers are seeking materials that combine strength with reduced weight. Advanced 3D printing filaments like Carbon Fiber Nylon, Carbon Fiber PEKK, Carbon Fiber Ultem, and Glass Fiber composites are enabling the next generation of strong, lightweight, and reliable parts.

Why Lightweighting Matters

Reducing part weight without sacrificing strength is critical for improving performance and lowering costs. In aerospace, every pound saved can translate into significant fuel efficiency. In automotive, lightweight parts improve fuel economy and EV battery life. For defense and UAVs, reduced weight allows for longer missions and improved payload capacity.

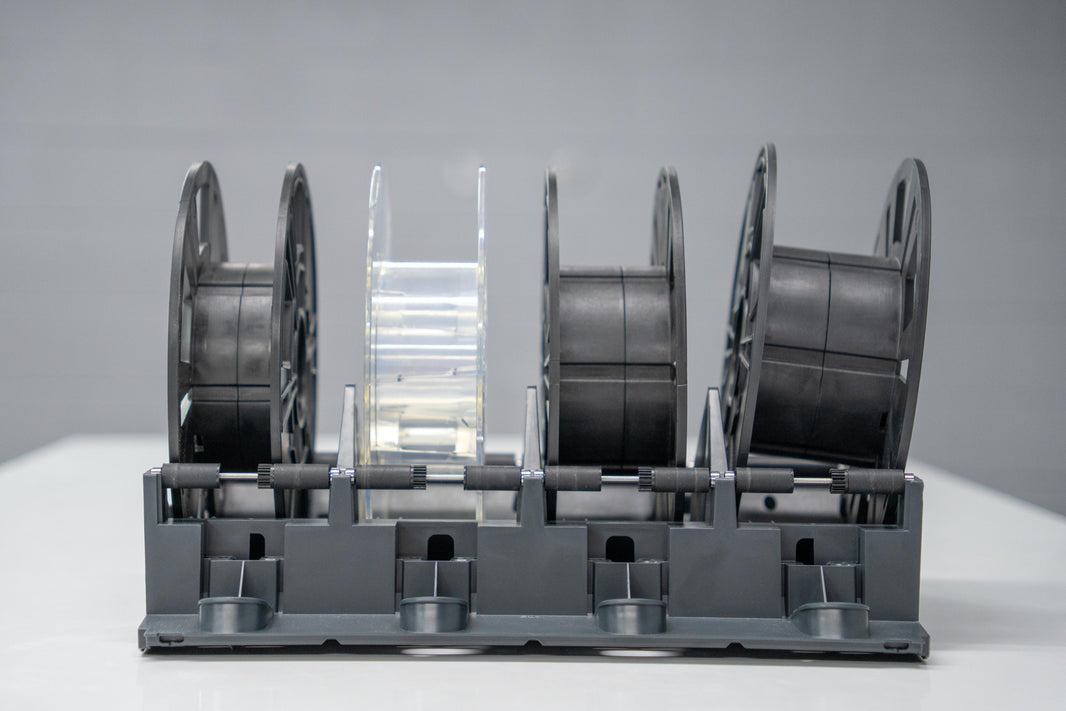

Top Lightweighting 3D Printing Filaments

- Carbon Fiber Nylon: A versatile engineering-grade filament with high strength-to-weight ratio, ideal for tooling, jigs, fixtures, and end-use components.

- Carbon Fiber PEKK: Combines extreme mechanical performance with lightweighting benefits for aerospace and defense parts in harsh environments.

- Carbon Fiber Ultem (PEI): A high-performance thermoplastic with outstanding flame resistance, chemical resistance, and lightweight structural strength.

- Glass Fiber Composites: Offering high stiffness and excellent dimensional stability, glass fiber filaments are a cost-effective solution for structural components.

Industry Applications

Lightweighting with advanced filaments is opening doors across industries:

- Aerospace: Lightweight brackets, housings, and interior components.

- Automotive: Structural prototypes, performance parts, and lightweight EV components.

- UAVs & Drones: High-strength, lightweight airframes and parts to extend flight time and payload capacity.

- Defense: Rugged yet lightweight equipment and vehicle components for demanding missions.

- Industrial Manufacturing: Lightweight jigs, fixtures, and end-of-arm tooling for robotics.

Benefits of Lightweighting with Advanced Filaments

- Fuel & Energy Efficiency: Reduced part weight contributes directly to operational savings.

- Improved Performance: Stronger yet lighter parts enhance speed, payload, and durability.

- Design Flexibility: 3D printing allows for complex geometries optimized for weight reduction.

- Cost Savings: Lower material use and improved efficiency lead to long-term savings.

Conclusion

Advanced lightweight 3D printing filaments like Carbon Fiber Nylon, Carbon Fiber PEKK, Carbon Fiber Ultem, and Glass Fiber composites are redefining what’s possible in additive manufacturing. Engineers can now design and produce parts that deliver strength, durability, and reduced weight—meeting the demands of aerospace, automotive, defense, UAV, and industrial applications.