Rapid Prototyping with Engineering-Grade Filaments: From Concept to Functional Testing

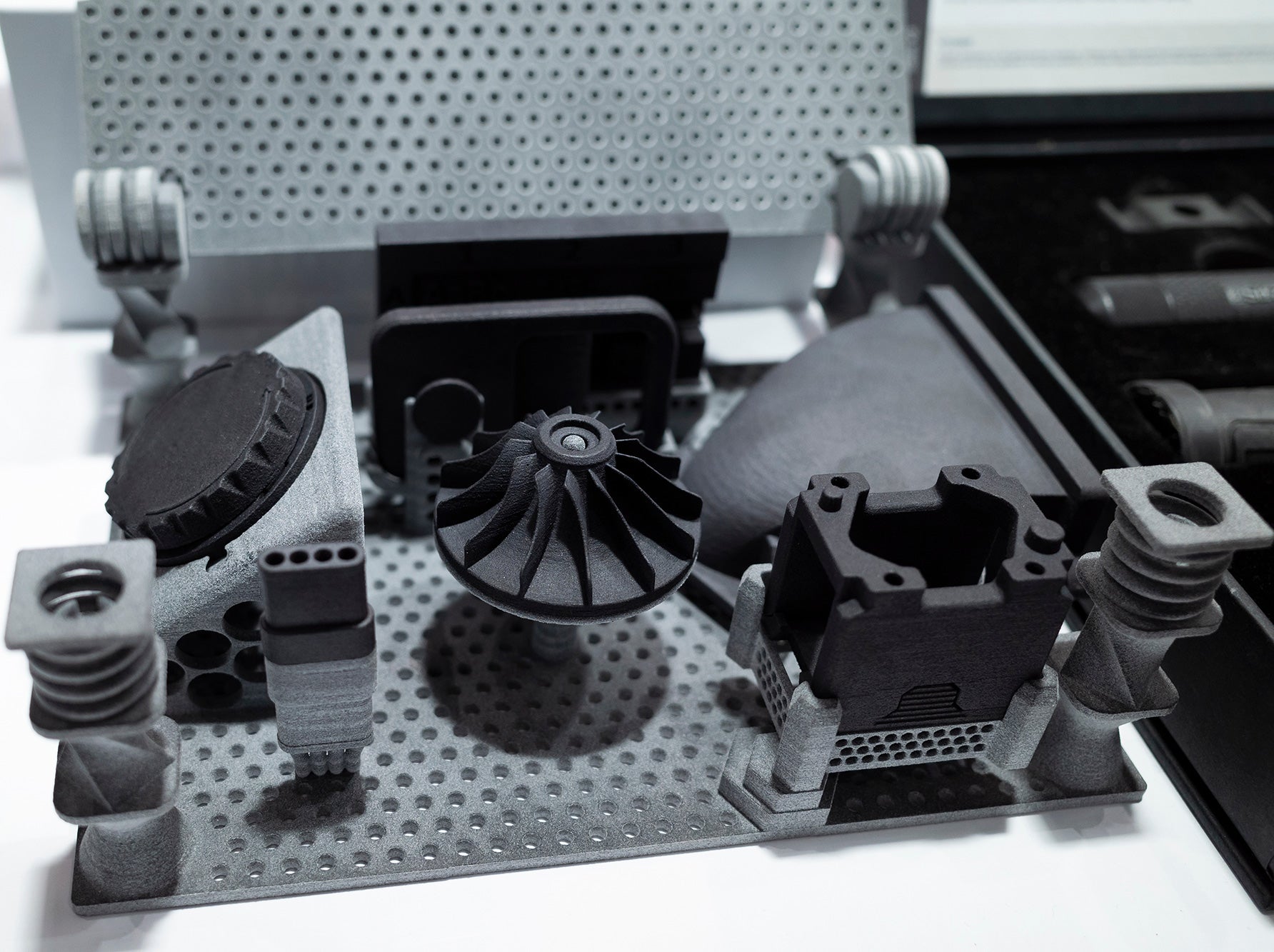

In today’s fast-paced product development cycle, rapid prototyping with engineering-grade filaments is transforming the way engineers move from concept to functional testing. Unlike standard prototyping materials, advanced thermoplastics such as Nylon, Polycarbonate, PEEK, and ULTEM offer the strength, heat resistance, and durability required for real-world testing.

By leveraging these industrial 3D printing materials, engineers in aerospace, automotive, defense, manufacturing, and oil & gas can shorten design cycles, reduce costs, and accelerate time-to-market.

Why Choose Engineering-Grade Filaments for Prototyping?

Traditional rapid prototyping often relies on inexpensive plastics for early-stage design validation. While these materials are sufficient for form and fit checks, they fall short when prototypes need to undergo functional testing. This is where engineering filaments make the difference:

- High strength-to-weight ratios, comparable to metals

- Excellent thermal stability for high-temperature environments

- Chemical and wear resistance for harsh applications

- Ability to produce end-use quality prototypes ready for testing

The result: prototypes that aren’t just visual models, but functional parts capable of withstanding demanding real-world conditions.

Key Engineering-Grade Filaments for Rapid Prototyping

Nylon Filament

Nylon filament is known for its toughness and flexibility, making it ideal for functional prototypes that require impact resistance and wear performance. Carbon Fiber and Glass Fiber reinforced Nylons enhance stiffness and dimensional stability.

Polycarbonate Filament

Polycarbonate filament is widely used for prototyping high-strength parts that need to withstand heat and mechanical stress. It’s especially useful in the automotive and aerospace industries for testing load-bearing components.

PEEK and PEKK Filaments

PEEK and PEKK filaments deliver exceptional thermal resistance and mechanical performance, allowing engineers to create prototypes that are nearly indistinguishable from production-grade parts. Ideal for oil & gas, aerospace, and defense testing environments.

ULTEM (PEI) Filament

ULTEM filament (PEI) provides a cost-effective alternative to PEEK and PEKK while maintaining high strength and compliance with aerospace and FDA standards. Commonly used for tooling, fixtures, and functional prototypes.

Applications Across Industries

Engineering-grade filaments unlock the potential for rapid prototyping in mission-critical sectors:

- Aerospace: Interior panels, brackets, and ducting prototypes for fit and functional validation

- Automotive: Under-the-hood components and lightweight structural parts for stress testing

- Defense: High-strength prototypes for mission-ready equipment and hardware

- Manufacturing: Rapidly printed jigs, fixtures, and tooling for production lines

- Oil & Gas: Prototypes of seals, housings, and connectors tested in harsh chemical environments

From Concept to Functional Testing

Rapid prototyping with advanced filaments follows a straightforward process:

- Concept Development: Initial designs are 3D printed for form and fit validation.

- Material Selection: Engineers choose the right filament based on strength, temperature, and chemical resistance needs.

- Functional Testing: Prototypes are tested under real-world conditions to validate performance.

- Design Iteration: Feedback drives improvements before final production.

This cycle allows companies to move from concept to validated product faster, saving time and resources.

Conclusion: The Future of Prototyping

With engineering-grade filaments, rapid prototyping is no longer limited to early-stage design validation—it’s a complete process that supports functional testing and end-use readiness.

By adopting advanced thermoplastics like Nylon, Polycarbonate, PEEK, PEKK, and ULTEM, engineers can bridge the gap between prototype and production, delivering reliable solutions across aerospace, automotive, defense, manufacturing, and oil & gas industries.