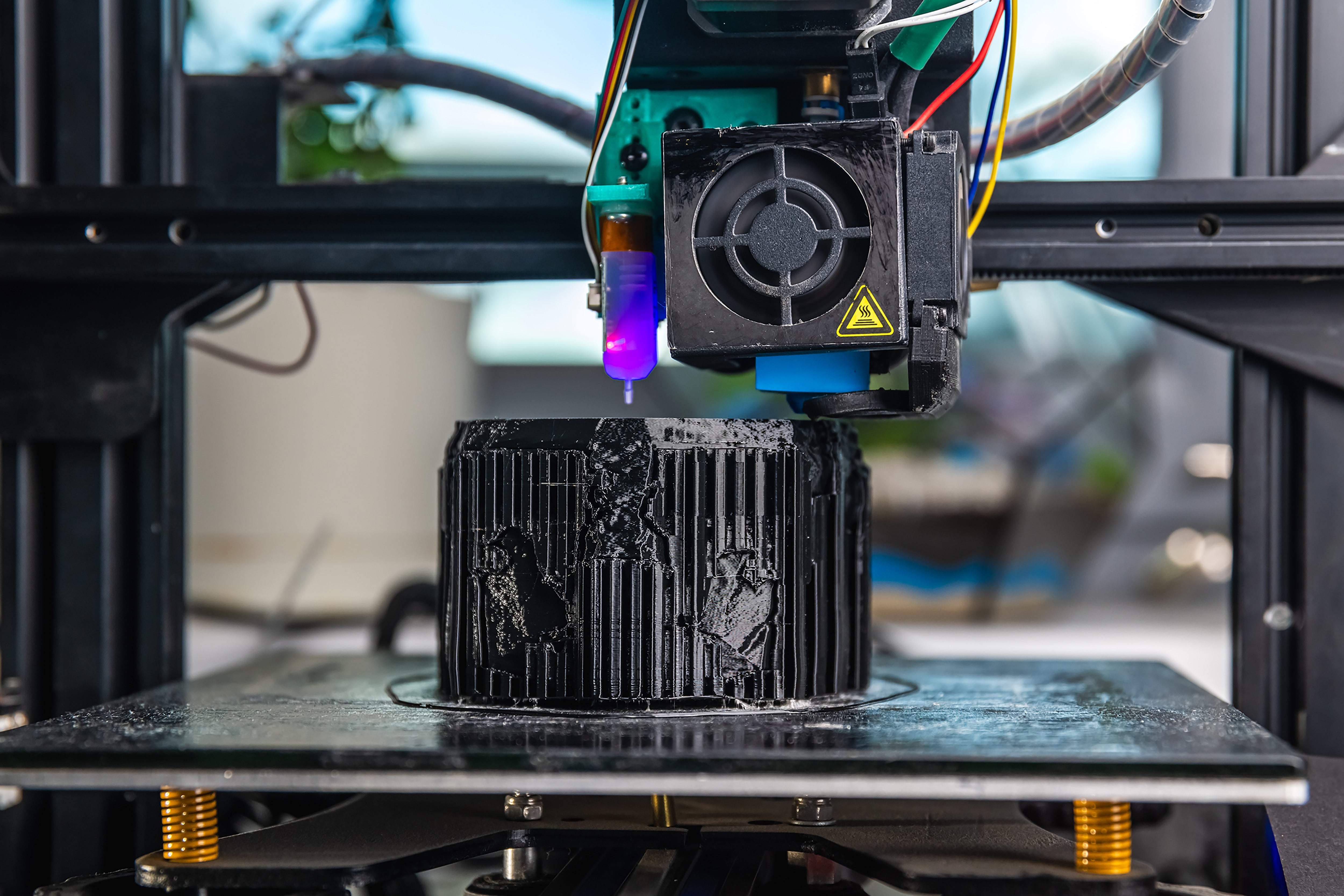

Under-extrusion means your printer isn’t feeding enough material, resulting in weak, incomplete prints with gaps. It’s often linked to clogged nozzles, filament issues, or incorrect settings. Left unresolved, it can compromise both print quality and strength.

Symptoms:

-

Thin, weak walls.

-

Visible gaps in layers.

-

Sparse extrusion lines.

Causes:

-

Partially clogged nozzle.

-

Filament diameter mismatch.

-

Extruder gear slipping.

-

Low extrusion multiplier.

Troubleshooting Steps:

-

Clean nozzle with cold pull or replace.

-

Check filament diameter matches slicer.

-

Adjust extrusion multiplier.

-

Verify extruder steps/mm calibration.

Prevention Tips:

-

Perform periodic cold pulls to keep nozzle clean.

-

Calibrate extruder regularly.