3D Printing for Aerospace: High-Performance Filaments Taking Flight

The aerospace industry demands materials that deliver unmatched strength, lightweighting, flame resistance, and reliability. As additive manufacturing continues to expand, high-performance 3D printing filaments such as PEEK, PEKK, Ultem (PEI), PPSU, PC, and Carbon Fiber composites are transforming the way engineers design, prototype, and manufacture flight-ready parts.

Why Aerospace Needs High-Performance Filaments

Every component in an aircraft must withstand extreme conditions, from high heat and pressure to rigorous safety standards. Traditional manufacturing methods often struggle with cost, weight, and lead times. 3D printing with engineering-grade filaments enables aerospace engineers to produce complex, lightweight, and durable components faster while meeting strict regulatory requirements.

Top Aerospace 3D Printing Filaments

- PEEK: Exceptional heat and chemical resistance, ideal for high-performance aerospace components.

- PEKK: Offers similar strength to PEEK with improved printability and flame resistance.

- Ultem (PEI): Known for outstanding flame retardancy (UL94 V-0) and lightweight strength for cabin interiors.

- PPSU: Excellent hydrolytic stability and toughness for aerospace fluid systems and housings.

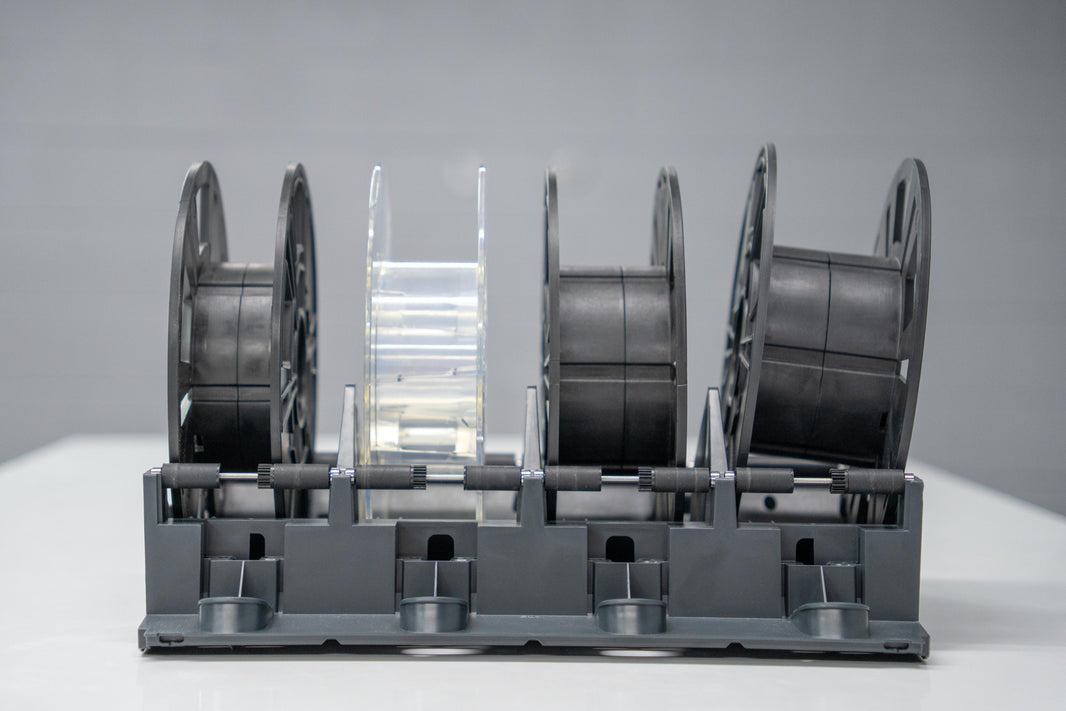

- Polycarbonate (PC): High impact resistance and clarity for durable tooling and non-structural components.

- Carbon Fiber: Deliver lightweight stiffness and strength, making them ideal for structural brackets and housings.

Aerospace Applications of 3D Printing Filaments

Engineers are increasingly adopting advanced filaments for critical aerospace applications, including:

- Cabin Interior Components: Lightweight, flame-retardant parts such as panels, ducting, and seating supports.

- Structural Brackets & Housings: Strong yet lightweight replacements for metal parts.

- Tooling & Fixtures: Custom jigs, fixtures, and molds that reduce lead times and costs.

- Prototyping & Testing: Functional prototypes that withstand real-world aerospace conditions.

Benefits of High-Performance Filaments in Aerospace

- Lightweighting: Significant weight savings compared to metals, improving fuel efficiency and performance.

- Flame Resistance: Materials like Ultem and PEKK meet aerospace flame, smoke, and toxicity requirements.

- Durability: Withstand extreme temperatures, chemicals, and mechanical stress.

- Faster Production: Additive manufacturing reduces lead times for both prototypes and end-use parts.

Conclusion

3D printing is reshaping aerospace manufacturing, and high-performance filaments are at the core of this transformation. Materials like PEEK, PEKK, Ultem, PPSU, PC, and Carbon Fiber composites enable aerospace engineers to produce lightweight, durable, and flame-retardant components that meet strict industry standards—while unlocking faster design cycles and greater innovation in the skies.