27 Common FDM 3D Printing Problems and How to Fix Them

Table of Contents

- Poor First Layer

- Bed Adhesion

- Under-Extrusion

- Over-Extrusion

- Stringing / Oozing

- Warping

- Overheating / Sagging

- Layer Shifts

- Layer Bonding Issues

- Grinding Filament at Drive Gears

- Gaps Between Walls and Infill

- Curling Corners

- Top Surface Artifacts

- Floor Corner Gaps

- Poor Wall Surface Finish

- Vibration-Related Defects

- Thin Wall Gaps

- Small Feature Printing

- Inconsistent Extrusion Rate

- Top Layer Gaps

- Poor Support Interface Surface

- Dimensional Accuracy

- Poor Bridging

- Clogged Extruder

- Ghost Printing

- Poor Infill Quality

- Blobs/Zits and Surface Defects

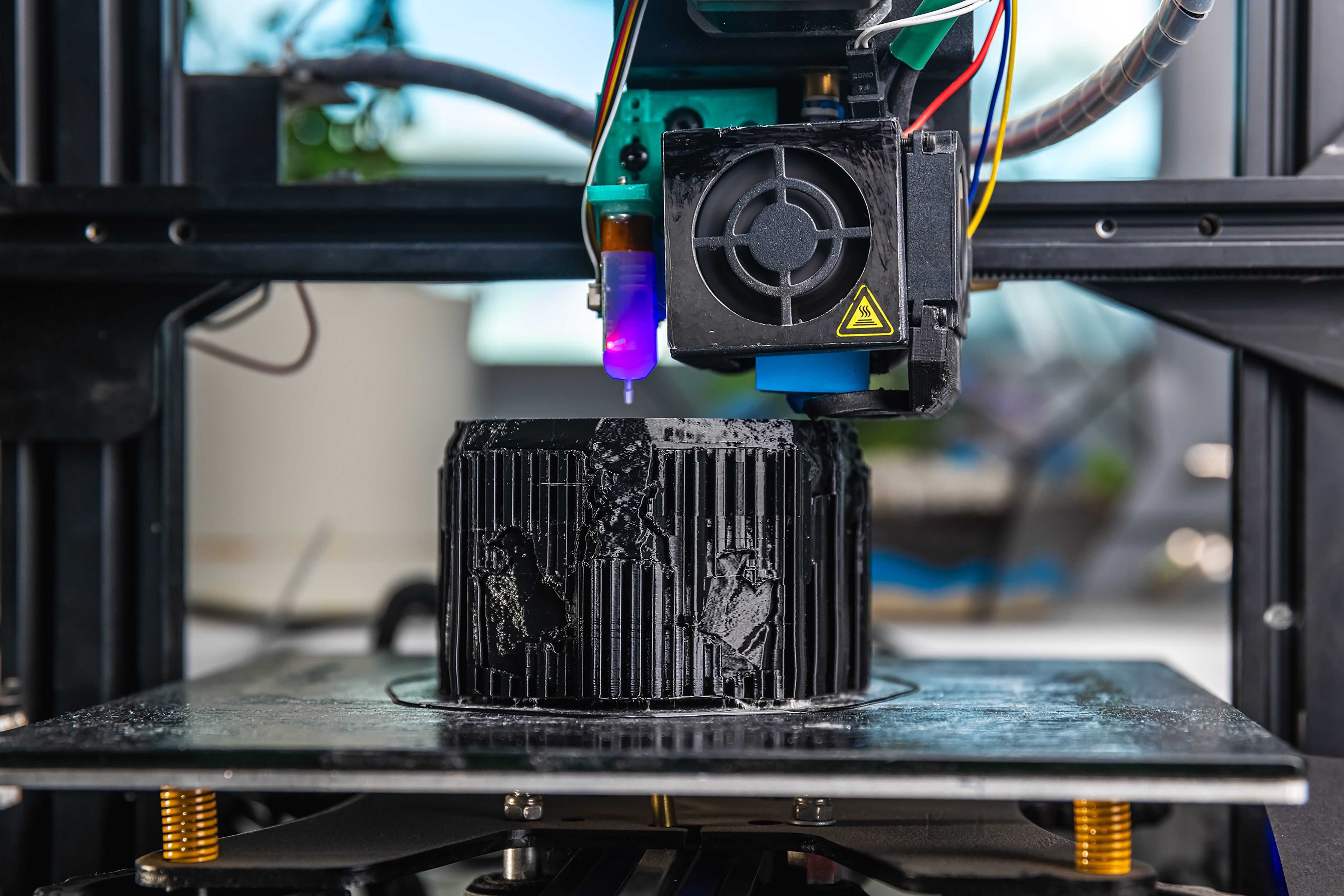

Introduction

3D printing with FDM is a powerful tool for prototyping and manufacturing, but common issues can frustrate even experienced makers. From poor first layers to blobs, gaps, and ghosting, understanding the symptoms and causes of each problem is key to consistent, high-quality prints. This guide covers 27 of the most common FDM issues, with practical fixes, prevention tips, and naturally integrated search-friendly phrases so you can quickly find the solution you need.

Many issues are interrelated—for example, poor first layer often contributes to bed adhesion problems, which can lead to warping or curling corners.

1. Poor First Layer

A bad first layer can ruin an entire print. Users searching for “3D print bad first layer” or “first layer not sticking FDM” often encounter uneven extrusion, gaps, or peeling corners.

- Symptoms: Uneven extrusion, gaps, peeling corners.

- Causes: Bed not leveled, nozzle too high/low, incorrect temperature.

- Fix: Re-level the bed, adjust nozzle height, calibrate first layer extrusion.

- Prevention: Keep the bed clean and run test prints regularly.

Tip: Fixing the first layer can prevent related issues like bed adhesion and floor corner gaps.

2. Bed Adhesion

Weak bed adhesion causes lifted corners and warping. Search terms include “3D print bed adhesion problem” or “print not sticking”.

- Symptoms: Corners lift, parts detach, warping edges.

- Causes: Dirty bed, wrong bed temperature, material shrinkage.

- Fix: Clean bed, apply adhesives (glue stick, PEI), adjust temperatures.

- Prevention: Match adhesives to filament type and keep bed clean.

Tip: Proper adhesion helps prevent warping and curling corners.

3. Under-Extrusion

Insufficient filament feeding leads to weak prints. Search terms: “under extrusion 3D printing”, “missing layers FDM”.

- Symptoms: Gaps in walls, thin lines, weak layers.

- Causes: Clogged nozzle, incorrect flow rate, filament slip.

- Fix: Check nozzle for blockage, calibrate extruder, dry filament.

- Prevention: Use quality filament and maintain extruder.

Tip: Can cause gaps between walls and infill and top layer gaps.

4. Over-Extrusion

Excess filament creates blobs, zits, and dimensional issues. Search: “over extrusion 3D printing”.

- Symptoms: Bulging walls, surface blobs, elephant’s foot.

- Causes: High flow rate, overheated hotend.

- Fix: Reduce extrusion multiplier, calibrate E-steps, lower temperature.

- Prevention: Tune flow settings regularly.

Tip: Can worsen poor wall surface finish and surface defects.

5. Stringing / Oozing

Thin strands of plastic appear across gaps. Search: “3D print stringing” or “oozing FDM printer”.

- Symptoms: Hairlike strings, messy surfaces.

- Causes: Poor retraction, hotend too hot, leaky nozzle.

- Fix: Tune retraction, lower nozzle temp, enable wipe/coast.

- Prevention: Store filament dry, test retraction.

Tip: Can affect small feature printing and top surface artifacts.

6. Warping

Edges lift due to filament shrinkage. Search: “3D print warping”.

- Symptoms: Lifted corners, deformed edges.

- Causes: Poor bed adhesion, cooling too fast, high shrinkage filament.

- Fix: Use heated bed, proper bed adhesive, reduce cooling fan speed initially.

- Prevention: Ensure good first layer and adhesion.

Tip: Prevents curling corners and floor corner gaps.

7. Overheating / Sagging

Overheating causes soft layers to sag. Users search: “3D print sagging” or “layer overheating FDM”.

- Symptoms: Drooping layers, deformed vertical surfaces.

- Causes: Hotend too hot, slow fan cooling, dense infill without support.

- Fix: Lower nozzle temperature, increase fan speed, print slower.

- Prevention: Monitor hotend temperature and layer cooling.

Tip: Can affect top surface artifacts and wall surface finish.

8. Layer Shifts

Misaligned layers result in a shifted print. Search: “3D print layer shift”.

- Symptoms: Layers misaligned, skewed shapes.

- Causes: Loose belts, stepper motor skipping, mechanical obstruction.

- Fix: Tighten belts, check pulleys, ensure smooth axis movement.

- Prevention: Regularly maintain printer mechanics.

Tip: Layer shifts worsen dimensional accuracy.

9. Layer Bonding Issues

Weak bonding causes fragile prints. Search: “3D print layer adhesion”.

- Symptoms: Layers separate easily, weak vertical strength.

- Causes: Low extrusion temperature, too fast printing, improper cooling.

- Fix: Increase nozzle temperature, slow down print, optimize fan speed.

- Prevention: Choose filament-specific temperatures and slow first layers.

10. Grinding Filament at Drive Gears

Filament gets chewed by the extruder. Search: “filament grinding 3D printer”.

- Symptoms: Shredded filament, under-extrusion.

- Causes: Too much tension, nozzle blockage, poor filament quality.

- Fix: Reduce extruder tension, clear nozzle, use quality filament.

- Prevention: Monitor filament feed and store dry.

11. Gaps Between Walls and Infill

Prints have hollow sections. Search: “gaps between infill and walls”.

- Symptoms: Visible holes, weak internal structure.

- Causes: Under-extrusion, wrong flow settings, nozzle issues.

- Fix: Calibrate flow rate, clean nozzle, check extrusion multiplier.

- Prevention: Regularly check filament feed and nozzle cleanliness.

12. Curling Corners

Corners lift from the bed. Search: “3D print corners lifting”.

- Symptoms: Warped corners, uneven edges.

- Causes: Poor adhesion, rapid cooling, high shrinkage filament.

- Fix: Improve bed adhesion, use a brim or raft, reduce cooling initially.

- Prevention: Use heated bed and first layer adhesion aids.

13. Top Surface Artifacts

Uneven top layers or imperfections. Search: “3D print top surface defects”.

- Symptoms: Rough, bumpy top surfaces.

- Causes: Over-extrusion, sagging layers, insufficient infill.

- Fix: Reduce extrusion rate, slow down top layers, increase infill density.

- Prevention: Ensure proper first layers and layer cooling.

14. Floor Corner Gaps

Gaps at the bottom corners. Search: “floor corner gaps 3D print”.

- Symptoms: Empty corners, weak base.

- Causes: Poor first layer, under-extrusion, bed not level.

- Fix: Level bed, check first layer, increase extrusion if needed.

- Prevention: Always calibrate bed and nozzle before printing.

15. Poor Wall Surface Finish

Rough, uneven vertical surfaces. Search: “wall surface defects 3D print”.

- Symptoms: Visible layer lines, rough walls.

- Causes: Over/under-extrusion, vibration, nozzle wear.

- Fix: Calibrate extrusion, tighten belts, replace nozzle if worn.

- Prevention: Maintain printer and adjust flow rate.

16. Vibration-Related Surface Defects

Artifacts caused by printer vibrations. Search: “ghosting 3D print”.

- Symptoms: Repeating patterns, ripples on walls.

- Causes: Loose belts, fast acceleration, unstable frame.

- Fix: Tighten belts, reduce print speed and acceleration.

- Prevention: Place printer on stable surface and maintain frame.

17. Thin Wall Gaps

Thin or incomplete walls. Search: “thin wall 3D printing”.

- Symptoms: Gaps or weak walls.

- Causes: Nozzle too large for wall thickness, under-extrusion.

- Fix: Adjust wall thickness in slicer, calibrate extrusion.

- Prevention: Match nozzle diameter to model walls.

18. Small Feature Printing

Difficulty printing tiny details. Search: “small detail FDM printing”.

- Symptoms: Missing details, rough small features.

- Causes: Nozzle too large, over-extrusion, high speed.

- Fix: Use smaller nozzle, reduce speed, adjust flow rate.

- Prevention: Optimize slicer settings for small features.

19. Inconsistent Extrusion Rate

Filament flow varies during printing. Search: “inconsistent extrusion 3D printer”.

- Symptoms: Thin and thick lines, gaps.

- Causes: Clogged nozzle, worn gears, filament quality.

- Fix: Clean nozzle, replace worn parts, check filament.

- Prevention: Regular maintenance and high-quality filament.

20. Top Layer Gaps

Holes on top surfaces. Search: “top layer holes 3D printing”.

- Symptoms: Incomplete top layers, gaps.

- Causes: Under-extrusion, too low infill overlap.

- Fix: Increase extrusion, adjust infill overlap.

- Prevention: Calibrate flow and check slicer settings.

21. Poor Support Interface Surface

Rough surfaces where support touches the model. Search: “support interface defects”.

- Symptoms: Rough underside, blobs on model.

- Causes: High support density, poor slicer settings.

- Fix: Adjust support density and interface layers.

- Prevention: Optimize slicer support settings.

22. Dimensional Accuracy

Printed parts do not match intended dimensions. Search: “3D print dimensional inaccuracy”.

- Symptoms: Parts too large or small, misaligned holes.

- Causes: Calibration issues, over/under-extrusion.

- Fix: Calibrate steps/mm, check flow rate, test prints.

- Prevention: Routine calibration and test prints.

23. Poor Bridging

Filament droops between gaps. Search: “bridging problems 3D print”.

- Symptoms: Sagging lines across gaps.

- Causes: Cooling too slow, high speed, over-extrusion.

- Fix: Increase fan, reduce speed, optimize extrusion.

- Prevention: Use bridging tests to tune settings.

24. Clogged Extruder

No filament flows from nozzle. Search: “extruder clogged 3D printer”.

- Symptoms: No extrusion, clicking sounds.

- Causes: Dirt, burnt filament, moisture in filament.

- Fix: Clean or replace nozzle, dry filament.

- Prevention: Regular maintenance, dry storage of filament.

25. Ghost Printing

Echoes or shadows appear on walls. Search: “ghosting 3D print”.

- Symptoms: Repeating ripples along walls.

- Causes: Vibrations, loose belts, rapid movements.

- Fix: Tighten belts, slow down acceleration, reduce print speed.

- Prevention: Secure printer and frame, reduce mechanical resonance.

26. Poor Infill Quality

Weak or missing infill patterns. Search: “poor infill 3D printing”.

- Symptoms: Hollow spots, gaps inside print.

- Causes: Under-extrusion, low infill density, incorrect slicer settings.

- Fix: Increase infill density, calibrate flow rate, check slicer.

- Prevention: Optimize slicer settings for infill strength.

27. Blobs/Zits and Surface Defects

Uneven surface marks. Search: “blobs on 3D print”.

- Symptoms: Blobs, zits, rough patches.

- Causes: Retraction settings, over-extrusion, speed changes.

- Fix: Tune retraction, reduce extrusion multiplier, slow travel moves.

- Prevention: Calibrate retraction and extrusion consistently.