Discover how to print with high-performance filaments like PEEK, PEKK, and ULTEM. Learn about their properties, hardware needs, challenges, and best practices for industrial-grade 3D printing.

Article collaborated with Wevolver

In advanced manufacturing industries such as aerospace, automotive, and healthcare, there is a demand for materials that can withstand extreme conditions and maintain superior mechanical and chemical properties. These sectors typically require components with exceptional strength, high thermal resistance, and chemical durability, which commodity plastics cannot provide. High-performance filaments such as PEEK, PEKK, and ULTEM can meet these demanding requirements. This article serves as a practical guide for users transitioning to these advanced materials, highlighting their characteristics, applications, required hardware, challenges, and considerations for successful printing.

Understanding High-Performance Filaments

High-performance filaments generally describe polymers that exhibit superior performance compared to standard engineering plastics in one or more key areas, such as thermal stability, mechanical strength, chemical resistance, or flame retardancy. These materials are designed to maintain their properties in harsh environments, making them suitable for critical applications.

PEEK: Strength and Heat Resistance

Polyether ether ketone (PEEK) is usually regarded as the benchmark for high-performance 3D printing filaments. It combines high tensile strength with excellent resistance to thermal and chemical degradation. With a tensile strength of about 100 MPa and a flexural modulus of roughly 8 GPa, PEEK provides high stiffness and strength relative to its low density of 1.39 g/cm³. Although its specific strength is somewhat lower than aluminum alloys, its combination of light weight, chemical resistance, and thermal stability makes it a candidate for replacing metals in demanding aerospace and automotive applications.

PEEK can operate in continuous service temperatures exceeding 250 °C, making it suitable for parts exposed to prolonged heat. PEEK also resists a wide range of chemicals, including hydrocarbons and organic solvents, allowing parts to maintain integrity in harsh environments characteristic of applications such as medical equipment, gas and oil processing, and aerospace.

PEKK: A Versatile Alternative

Polyether ketone ketone (PEKK) belongs to the same polymer family as PEEK but offers distinct processing advantages. It shares similar chemical and thermal resistance but differs in molecular structure, having an additional ketone group in its backbone. This structural variation influences how the polymer chains arrange during cooling, resulting in a lower crystallization rate. Consequently, PEKK can be printed more like an amorphous polymer, with less shrinkage and warping during cooling. However, it can also be post-treated to increase crystallinity, to enhance mechanical strength and chemical resistance for demanding applications. Therefore, PEKK is often chosen when users need comparable performance but seek a material with slightly more forgiving printability.

ULTEM (PEI): Thermal Stability and Certified Grades

Polyetherimide (PEI), generally recognized under the trade name ULTEM, is another high-performance filament. ULTEM is distinguished by its high glass transition temperature and mechanical strength, which makes it suitable for parts enduring operating conditions involving high heat and intense. ULTEM is available in aerospace-certified, flame-retardant formulations, including ULTEM 1010 and ULTEM 9085. These certified grades make it ideal for flight-ready components, interior parts in aircraft cabins, and safety-critical applications in other regulated industries.

Comparison with Standard Engineering Plastics

High-performance filaments like PEEK, PEKK, and ULTEM have advantages over widely used engineering plastics like ABS, Nylon, or PETG, in certain areas. ABS and PETG are sufficient for many general-purpose applications and offer ease of printing and affordability. Nylon, while stronger and more heat-resistant than ABS, still has limitations when exposed to extreme temperatures or aggressive chemicals. On the other hand, high-performance filaments maintain dimensional stability and structural integrity where these common materials could fail. Standard filaments may be sufficient for many everyday parts, while high-performance filaments are ideal for functional prototypes and production-grade components. Therefore, industries that prioritize reliability under demanding conditions are turning toward advanced polymers, despite their higher cost and more stringent printing requirements.

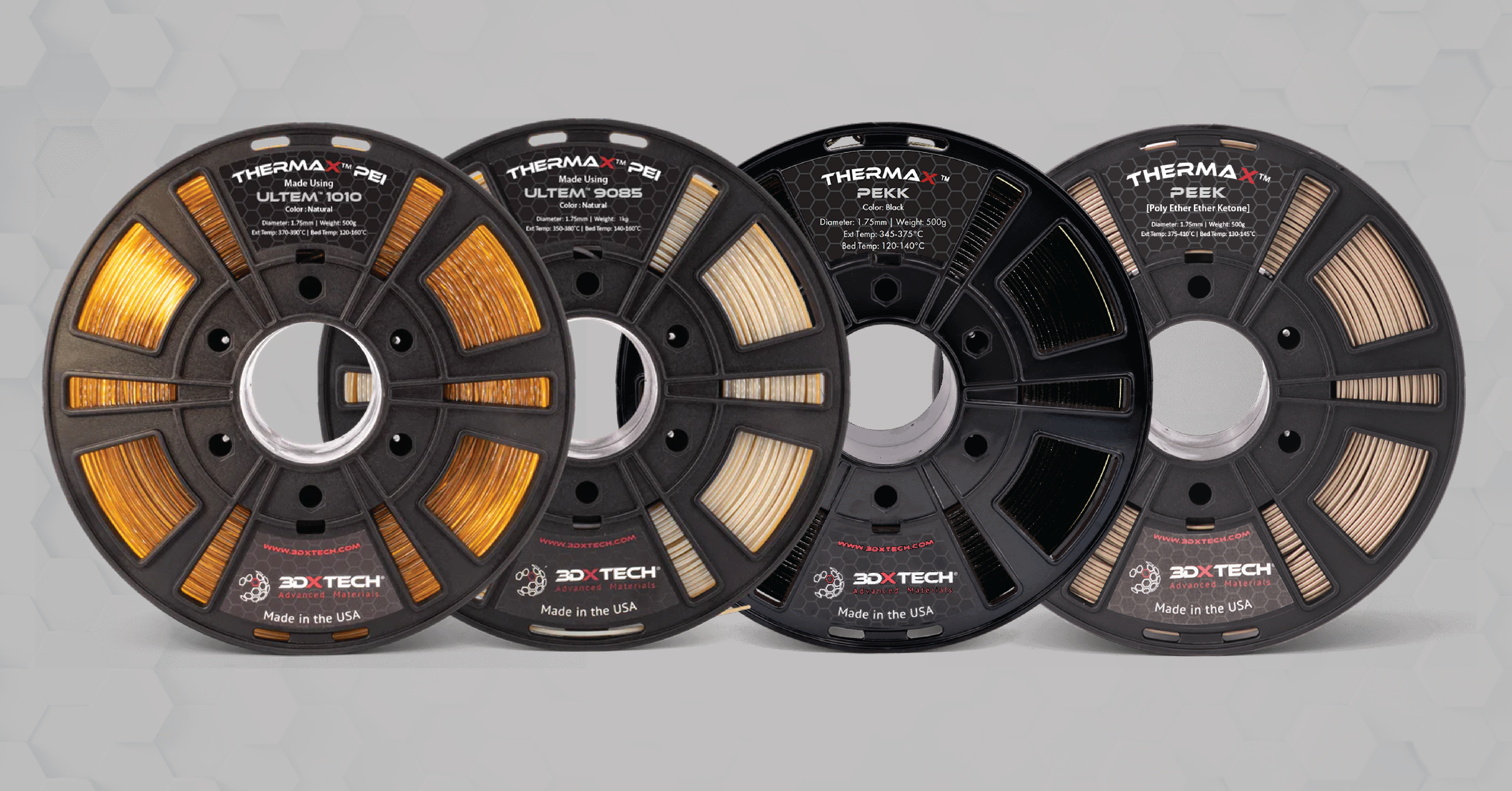

3DXTech’s High-Performance Portfolio

3DXTech has developed a range of high-performance filaments that bring these advanced polymers to the additive manufacturing market. For instance, CarbonX PEEK+CF combines the inherent strength and chemical resistance of PEEK with carbon fiber reinforcement to enhance stiffness and dimensional stability. ThermaX™ PEKK provides the versatility of PEKK with optimized printability for demanding applications. Similarly, ThermaX™ ULTEM offers aerospace-grade formulations such as ULTEM 1010 and ULTEM 9085 made with certified base resins for industries that require flame-retardant materials. These filaments enable high-performance printing for demanding applications such as aerospace brackets, under-hood automotive components, and sterilizable medical tools.

When to Use High-Performance Filaments?

Choosing high-performance polymers should be based on application requirements rather than novelty. These materials justify their higher costs and stricter processing needs in scenarios where standard engineering plastics fall short. For example, aerospace brackets often require not just lightweight but also resistance to continuous, high mechanical stresses and exposure to jet fuel, hydraulic fluids, and fluctuating temperatures. Similarly, under-hood automotive components endure constant mechanical loading while withstanding heat cycles and contact with oils and coolants. High-performance polymers are a more reliable choice in these environments, where common materials like ABS or PETG degrade quickly.

Similarly, non-human contact medical devices such as sterilization trays, housings, or equipment mounts that endure repeated autoclaving or exposure to harsh cleaning chemicals benefit from the stability of high-performance polymers. High-performance filaments are also used in housings for high-temperature electronics that require both thermal and chemical resilience to ensure long service life.

It is also important to recognize that not every project benefits from using such advanced polymers. For many functional prototypes, housings, or fixtures that operate in typical office or workshop conditions, more affordable materials such as PETG, ABS, or reinforced nylons provide adequate strength and temperature resistance. Using high-performance polymers in such cases can introduce unnecessary cost and complexity. For instance, a housing for a desktop device rarely requires the thermal stability of ULTEM. Hence, choosing it over a lower-cost engineering plastic may lead to overengineering without delivering real performance gains. Therefore, the decision to adopt high-performance filaments should be guided by a clear understanding of environmental stress, chemical exposure, regulatory requirements, and expected service life of the part.

Hardware Requirements for Successful Printing

High-performance polymers demand far more from 3D printing hardware than conventional materials. The properties that make them valuable— thermal stability, strength, and chemical resistance—also make them more challenging to process. Attempting to print them on standard desktop machines typically yields poor results, as these materials require very high extrusion and chamber temperatures.

For instance, extrusion requires sustained temperatures of 380 to 410 °C for polymers such as PEEK. Many prosumer-grade printers do not achieve these levels, which makes purpose-built high-temperature printers or heavily modified systems essential. The heated build plate is equally important, as the temperatures of around 130 to 150 °C are typically necessary to ensure that the first layers adhere securely to the surface and that shrinkage is minimized as the print cools. Beds that cannot reach or maintain these levels tend to produce parts with curling edges or inconsistent bases, both of which undermine dimensional accuracy.

One of the most decisive factors in hardware requirements is the heated build chamber. High-performance materials rely on uniform environmental heating for success. Heated build chamber sustains an elevated ambient temperature throughout the print, and reduces thermal gradients that lead to warping, delamination, and incomplete crystallization. For many high-temp materials, a heated chamber is not optional; it is required for parts to meet performance specifications. Parts may look intact immediately after printing without this control, but fail to meet the mechanical or thermal performance expected in demanding applications.

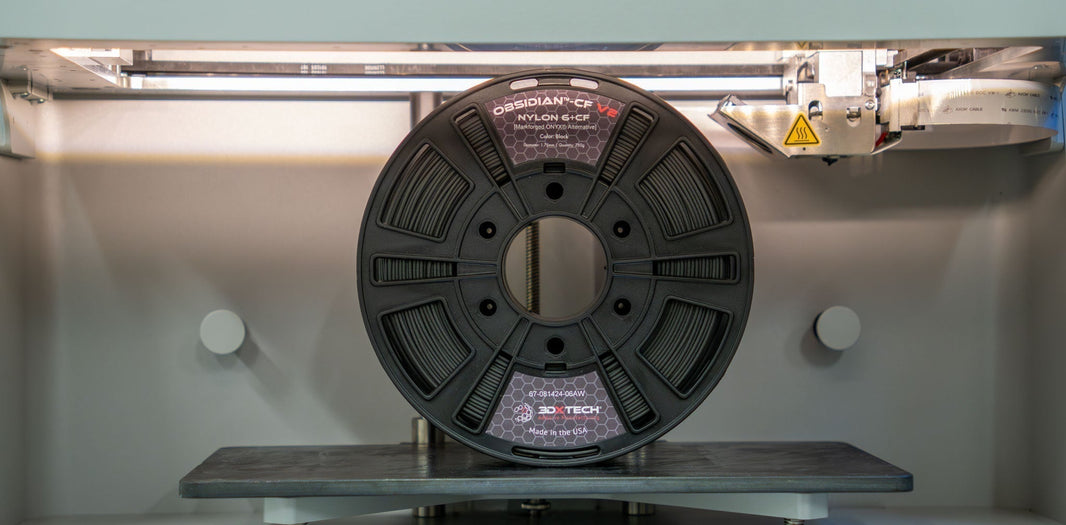

Filament handling is also critical. Materials such as PEEK and ULTEM may absorb moisture from the air, leading to bubbling, surface defects, and weakened parts during extrusion. Active drying systems or heated filament chambers integrated with the printer are therefore strongly recommended. These not only prepare the material before use but also maintain its condition during long build cycles, which is crucial given the extended printing times common with large or complex parts.

Although some prosumer machines can be modified to handle higher temperatures by retrofitting with specialised hotends, bed heaters, or enclosures, the results can be inconsistent. Printers designed from the ground up for high-performance polymers deliver more reliable, consistent performance by integrating all these requirements into a single system.

Challenges, Best Practices, and Do’s & Don’ts

Working with high-performance filaments presents a different set of challenges compared to standard engineering plastics. Users may encounter warping as parts cool unevenly, particularly with semi-crystalline polymers like PEEK and PEKK. Poor layer adhesion is another common issue, especially if the chamber temperature fluctuates or the material has not been properly conditioned. Moreover, these filaments are highly sensitive to moisture.

Preparation and environmental control are key to addressing these challenges. Filaments should always be dried before use, as even a brief exposure to ambient humidity can compromise print quality. Maintaining a stable chamber temperature throughout the print reduces the risk of layer separation and supports proper polymer crystallisation. Bed adhesion also requires more attention than with lower-temperature plastics. Surfaces like PEI build plates or the application of high-temperature adhesives can help parts remain anchored during long print cycles. Adjusting printing parameters, such as reducing the print speed for better interlayer bonding or fine-tuning the layer height to balance detail and mechanical strength, can also help further improve results.

There are also clear do’s and don’ts when it comes to high-performance filament handling. Do calibrate and monitor equipment regularly. Store filaments in dry, sealed containers or in active dryers when not in use. Experiment with adhesion methods appropriate to the chosen material. On the other hand, don’t attempt to print these polymers with low-temperature printers. Don’t skip drying cycles, as even brief exposure to ambient humidity can compromise results. Don’t assume success without adequate chamber heating.

3DXTech offers dedicated systems, such as the FM1 Filament Maintainer and the FD1 Filament Dryer, for reliable conditioning and storage, ensuring filaments are dry and ready for use. Incorporating these practices into the workflow helps users achieve the full potential of high-performance polymers.

Post-Processing and Performance Optimization

Once a part is printed, additional post-processing steps can further enhance its performance. Annealing is a common practice for semi-crystalline polymers such as PEEK and PEKK. Controlled heating of the printed part promotes higher crystallinity, which improves strength, dimensional stability, and thermal resistance.

Mechanical finishing methods such as machining, drilling, or polishing can refine tolerances or surface quality. This is very important for parts used in assemblies where fit and precision are critical. Vapor smoothing may be applicable in some cases, though not all high-temperature polymers are compatible with this technique. In critical applications, testing for dimensional stability and mechanical performance ensures parts meet design requirements.

Cost vs. Value Considerations

High-performance filaments and printers capable of processing them require a significant upfront investment. Materials such as PEEK or ULTEM are considerably more expensive than ABS or PETG, and high-temperature printers cost substantially more than standard systems.

However, cost should be evaluated in context. When these materials replace machined metal parts, they can reduce weight and simplify manufacturing, leading to long-term savings. Eliminating secondary machining or enabling in-house production can offset the higher material costs. Evaluating whether to adopt high-performance filaments involves weighing upfront expenses against part performance, lifecycle benefits, and manufacturing efficiency. For many businesses, the ability to produce complex, lightweight, and durable parts outweighs the initial costs.

Conclusion: Unlocking the Potential of Advanced Printing

High-performance filaments such as PEEK, PEKK, and ULTEM extend the capabilities of 3D printing into applications once limited to metals or specialized manufacturing methods. They offer exceptional strength, heat resistance, and chemical stability, but also introduce demanding processing requirements.

Users can achieve consistent and reliable results with the right equipment, careful filament handling, and disciplined printing practices. Post-processing techniques and proper evaluation can further enhance part performance, making these materials suitable for aerospace, automotive, medical, and electronic applications.

In this regard, companies like 3DXTECH offer a comprehensive portfolio, including CarbonX™ and ThermaX™ high-performance filaments, as well as FD1 and FM1 drying systems, to ensure consistent material quality. Their technical resources and support help users achieve reliable, high-quality prints that meet high-performance standards. Explore the 3DXTECH website to find out more.

References

-

3DXTech. [Online] Available at: https://www.3dxtech.com/ (Accessed on September 18, 2025)

-

CarbonX PEEK+CF10. [Online] 3DXTech. Available at: https://www.3dxtech.com/products/carbonx-peek-cf10-1 (Accessed on September 18, 2025)

-

THERMAX PEKK A. [Online] 3DXTech. Available at: https://www.3dxtech.com/products/pekk-a (Accessed on September 18, 2025)

-

ThermaX PEI 1010. [Online] 3DXTech. Available at: https://www.3dxtech.com/products/thermax-pei-1010 (Accessed on September 18, 2025)

-

ThermaX PEI 9085. [Online] 3DXTech. Available at: https://www.3dxtech.com/products/thermax-pei-9086 (Accessed on September 18, 2025)

-

FM1 - Filament Maintainer. [Online] 3DXTech. Available at: https://www.3dxtech.com/pages/fm1-filament-maintainer (Accessed on September 18, 2025)

-

FD1 - Filament Dryer [Online] 3DXTech. Available at: https://www.3dxtech.com/pages/fd1-filamentdryer (Accessed on September 18, 2025)