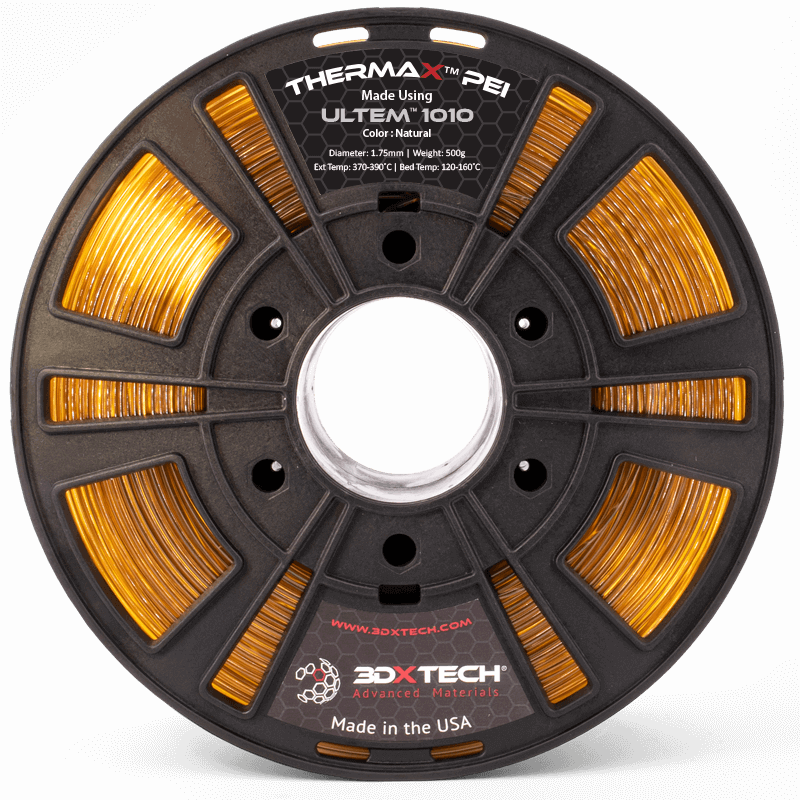

Ultra Performance Filaments

These are the strongest filaments on the market. These filaments contain unique properties such as high-temperature resistance, natural and synthetic solvent resistance, high dielectric strength and good thermal conductivity.

Shop Now

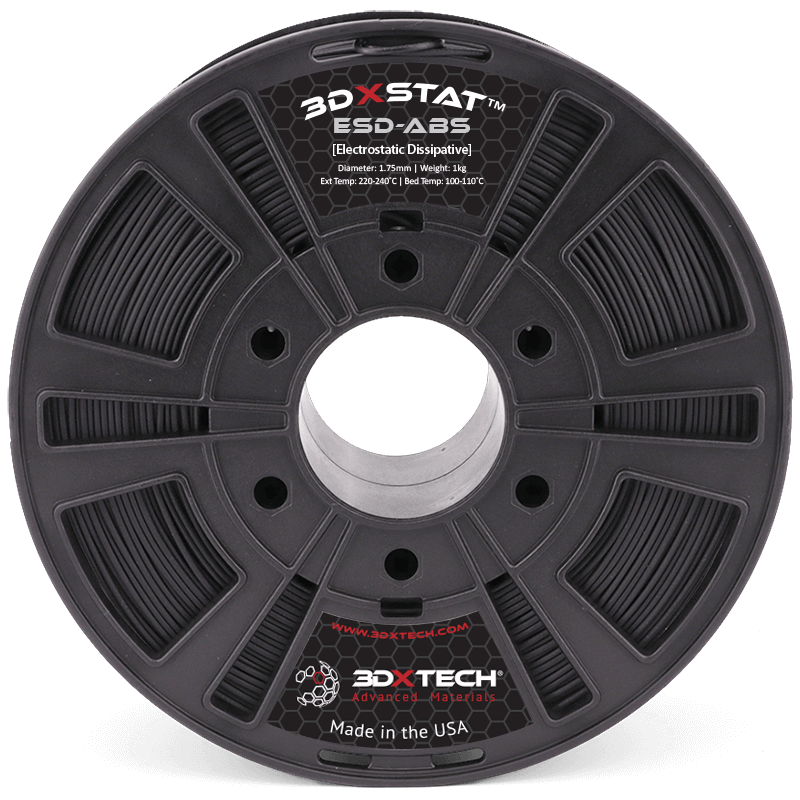

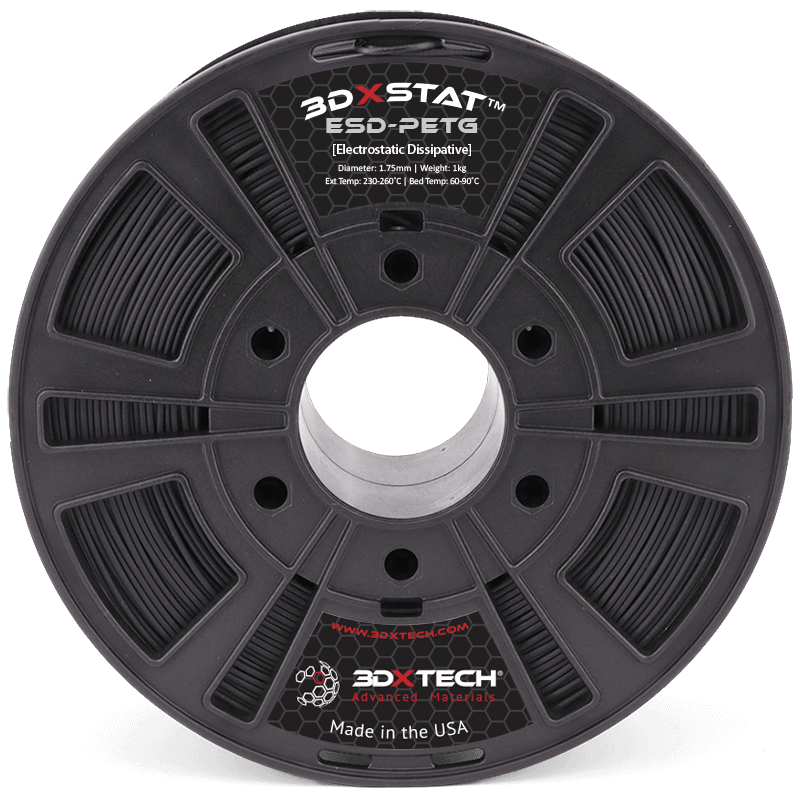

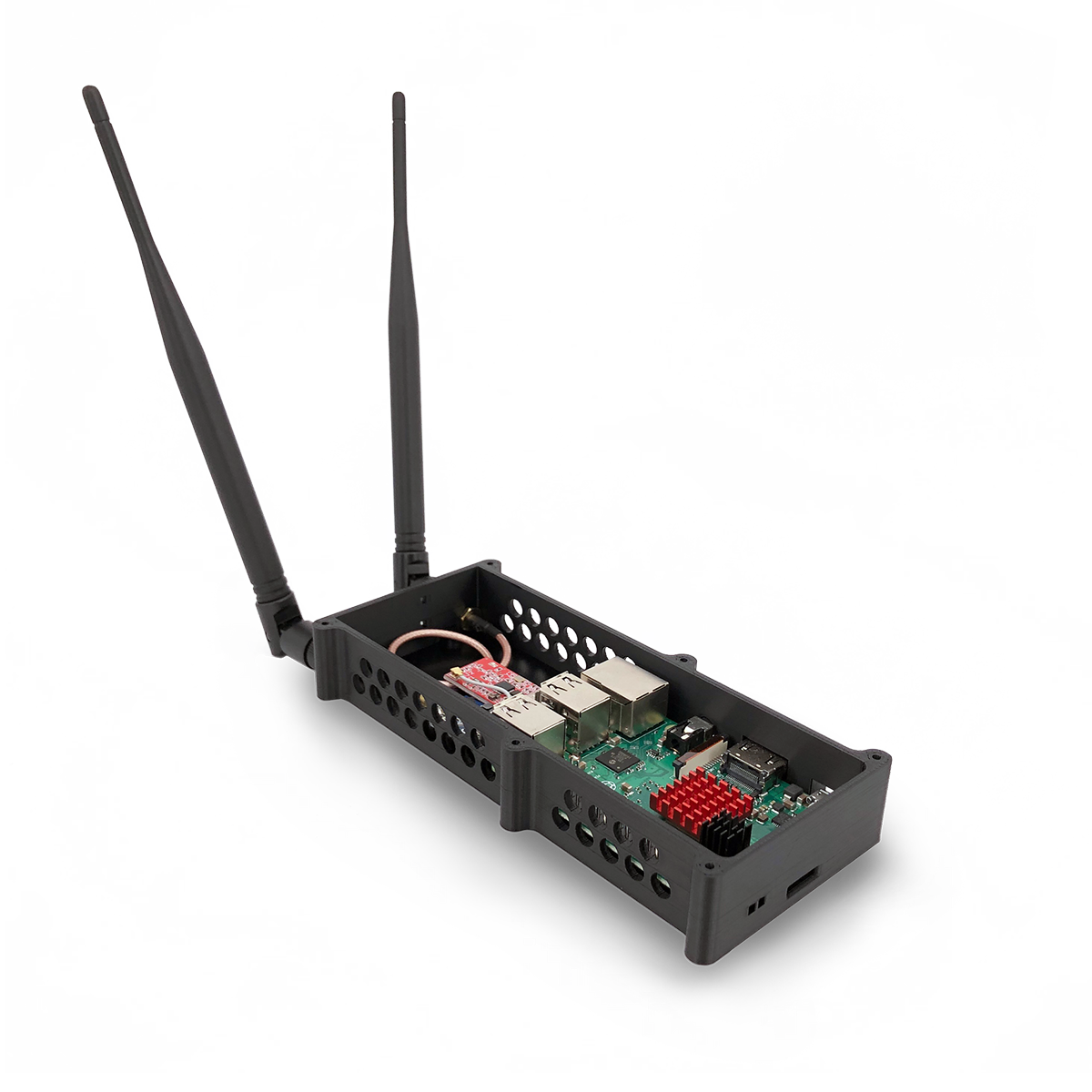

ESD-Safe Filament

Electrostatic discharge-safe, or ESD-safe, materials are essential for protecting sensitive electronics, ensuring industry compliance, and enhancing reliability across various sectors.

Shop Now

Carbon Fiber Filament

Carbon fiber 3D printing materials offer superior strength, stiffness, and durability, making them ideal for high-performance components across industries like aerospace, defense, and automotive. Their lightweight nature and resistance to wear and heat enhance performance and efficiency in sectors ranging from manufacturing to medical and oil and gas.

Shop Now

Flame Retardant Filaments

Flame retardant 3D printing materials enhance safety and performance across industries by reducing fire risks and ensuring compliance with safety standards. From aerospace and defense to electronics and automotive, these materials provide critical protection in high-stakes environments.

Shop Now