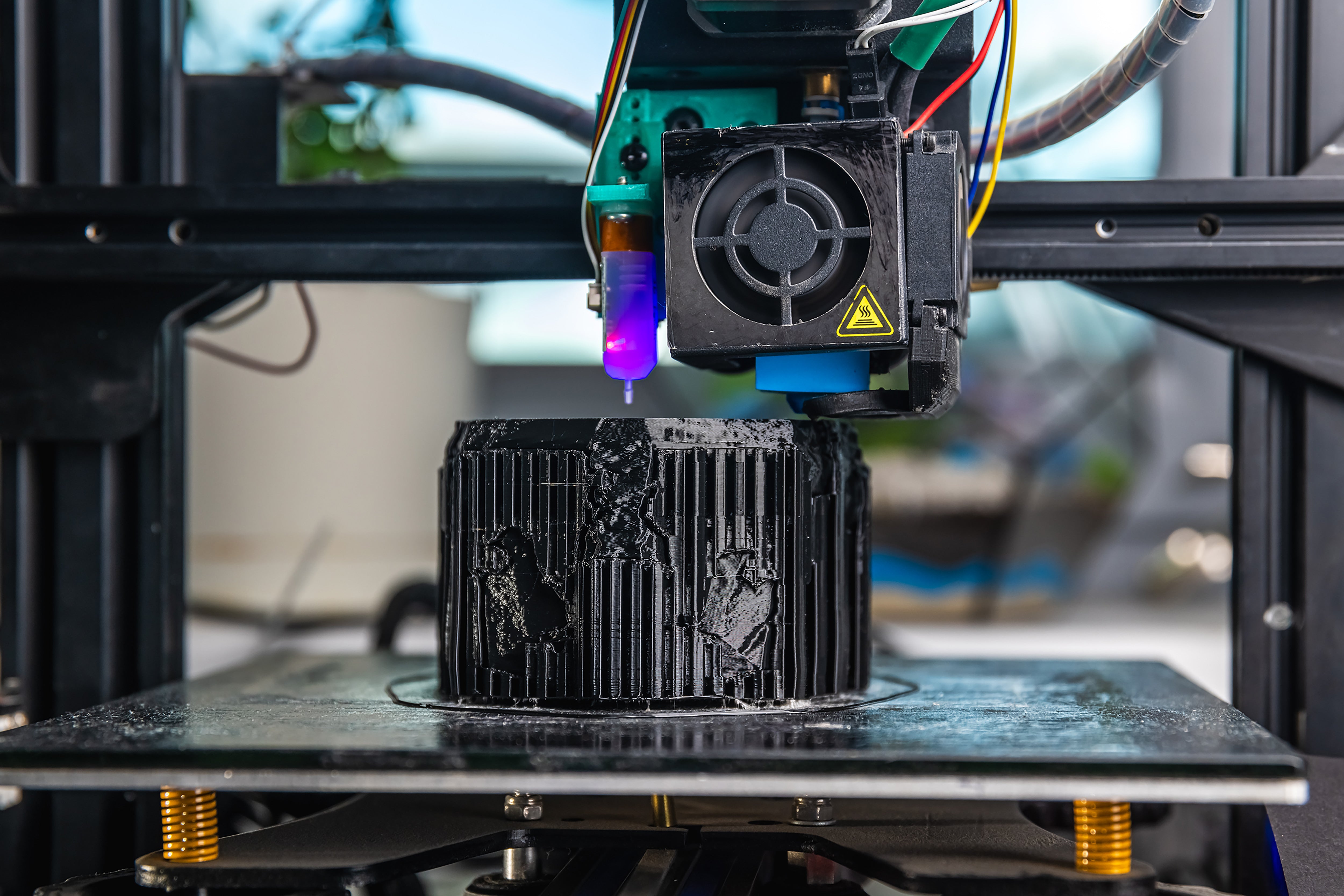

Curling corners are common when printing large flat parts. As layers cool unevenly, corners lift upward, leading to poor dimensional accuracy or even nozzle collisions. This problem is often tied to cooling settings and adhesion quality on the first few layers.

Symptoms:

-

Corners curl upward while rest of layer stays flat.

-

Edges cause nozzle to collide during print.

Causes:

-

Cooling fan too strong.

-

Bed adhesion weak at corners.

-

Uneven thermal contraction.

Troubleshooting Steps:

-

Reduce fan speed for first few layers.

-

Raise bed temp slightly.

-

Add brim to increase adhesion.

-

Print with enclosure for large ABS/nylon parts.

Prevention Tips:

-

Use draft shields in slicer.

-

Optimize first layer adhesion before longer prints.