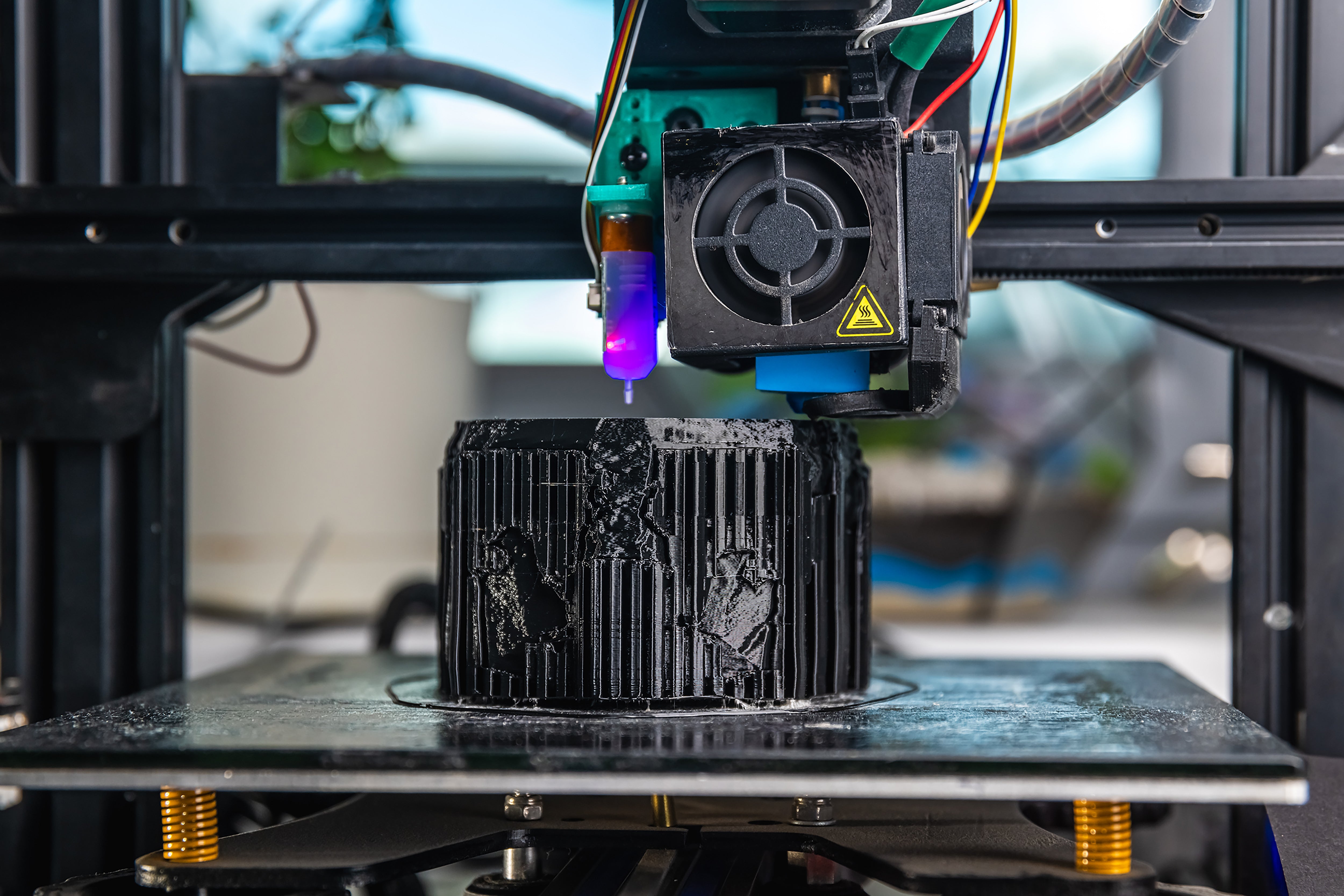

Over-extrusion happens when your printer extrudes too much material, causing blobs, zits, and dimensional inaccuracy. While less catastrophic than under-extrusion, it creates poor surface quality and prevents precision parts from fitting correctly.

Symptoms:

-

Bulging corners.

-

Rough, inconsistent surfaces.

-

Dimensional inaccuracies.

Causes:

-

Extrusion multiplier too high.

-

Incorrect filament diameter setting.

-

Overheating material flow.

Troubleshooting Steps:

-

Lower extrusion multiplier (flow rate).

-

Verify filament diameter in slicer.

-

Check for slicer bugs or multiple extrusion commands.

Prevention Tips:

-

Run calibration cubes to tune flow.

-

Use consistent filament suppliers for diameter accuracy.