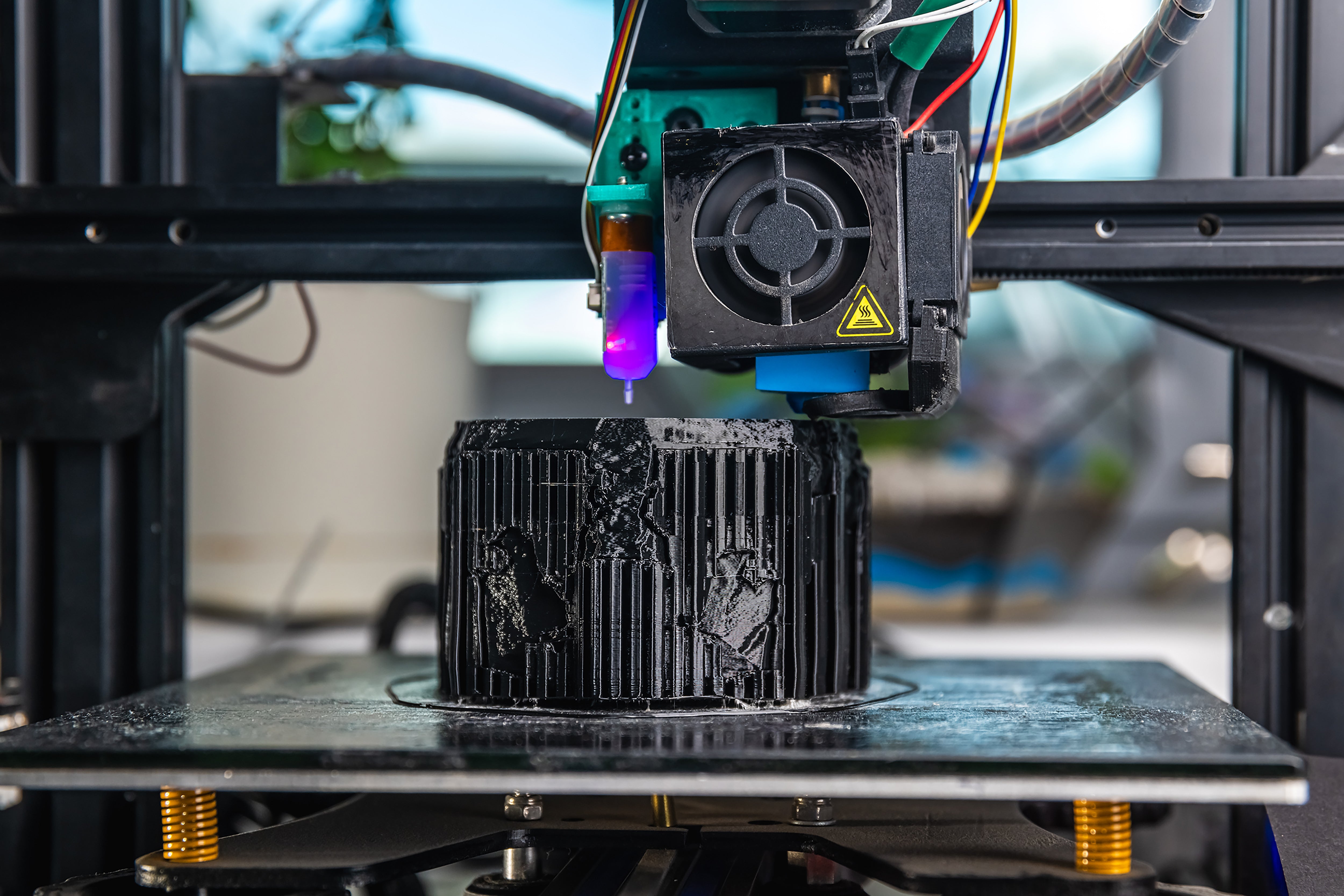

A clogged extruder halts printing and is one of the most frustrating issues. Clogs can result from debris, burned filament, or incompatible material residues. Keeping the extruder clean and using proper maintenance prevents most clogs.

Symptoms:

-

No filament extruding.

-

Clicking extruder motor.

-

Under-extrusion before complete blockage.

Causes:

-

Dust or debris in nozzle.

-

Burned filament residue.

-

Switching between materials without purging.

Troubleshooting Steps:

-

Perform a cold pull (a.k.a. “atomic pull”) to clear nozzle.

-

Heat nozzle and push filament manually.

-

Disassemble hotend if severe clog persists.

-

Replace nozzle if cleaning fails.

Prevention Tips:

-

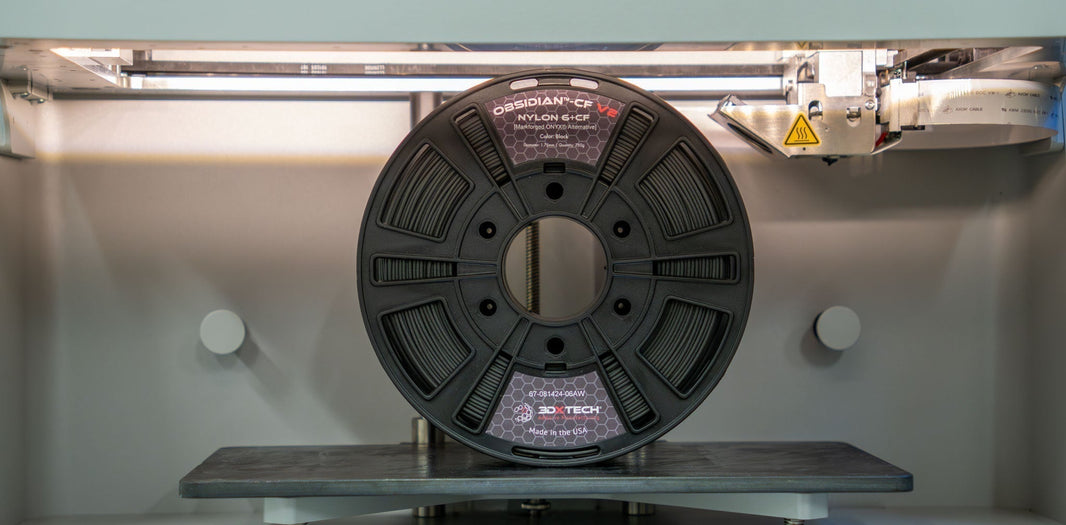

Use filament filters to prevent dust entry.

-

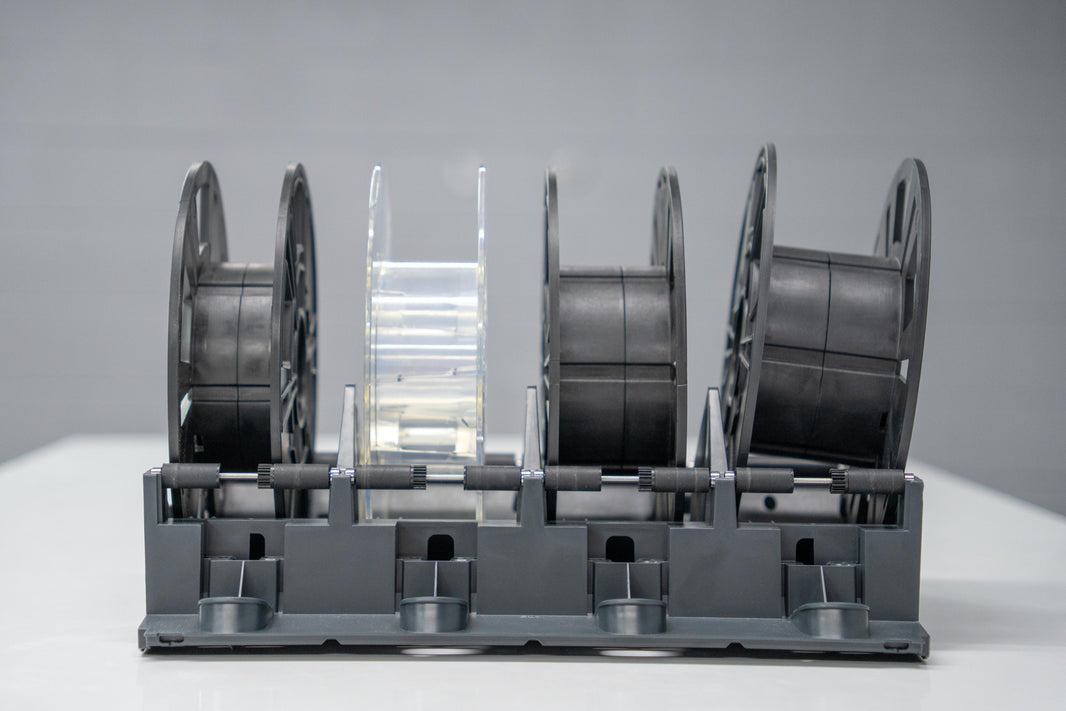

Store filament dry.

-

Purge hotend thoroughly when switching materials.