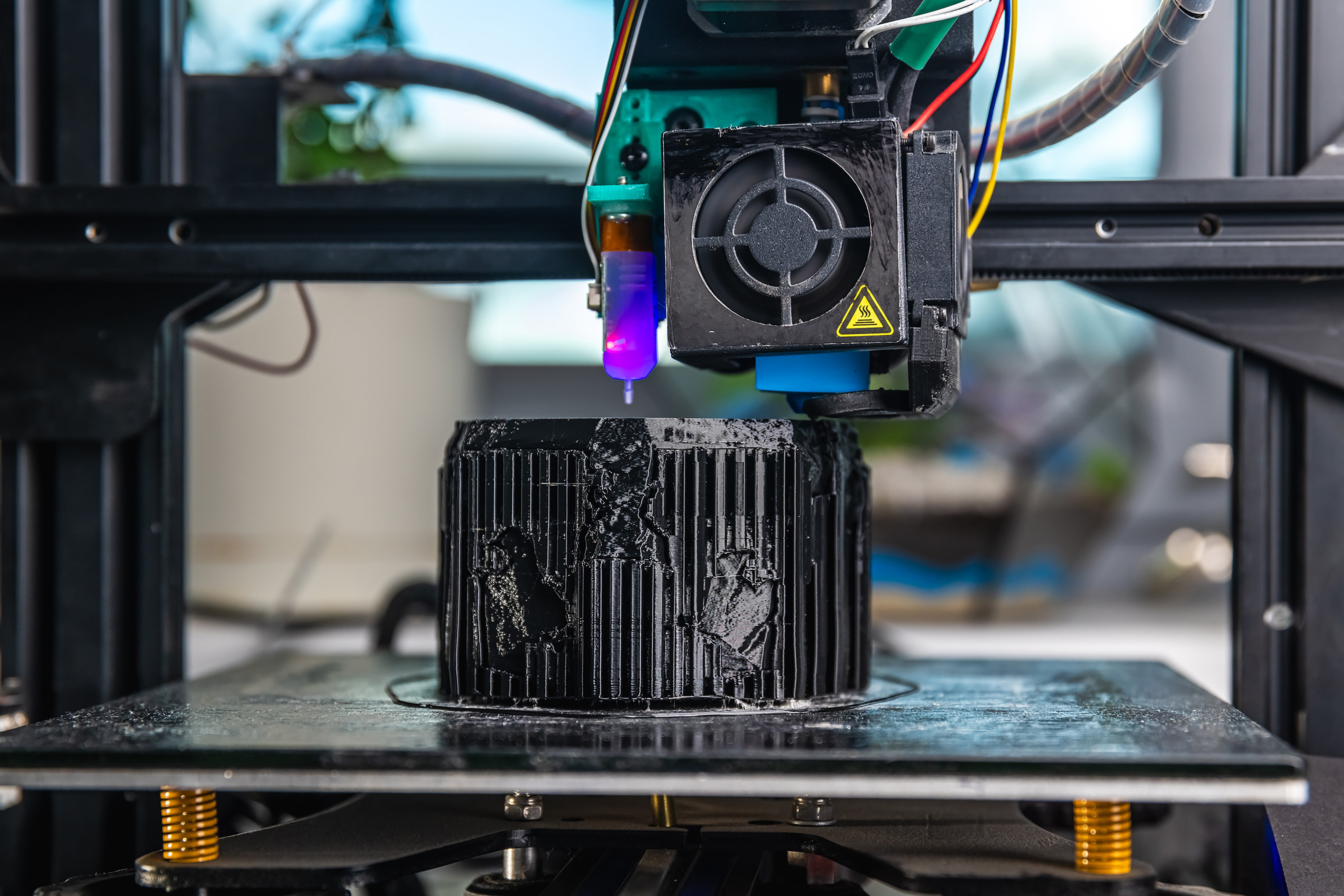

The outer walls of your print are the most visible, so rough or inconsistent surfaces can ruin the overall appearance. Poor wall surface finish often comes from mechanical vibrations, incorrect slicer settings, or extrusion inconsistencies. Improving wall quality helps both aesthetics and dimensional accuracy.

Symptoms:

-

Rough, uneven, or wavy wall surfaces.

-

Visible extrusion lines on walls.

-

Rippled or bumpy textures.

Causes:

-

Print speed too high.

-

Extruder temperature fluctuations.

-

Loose belts or frame components.

Troubleshooting Steps:

-

Reduce print speed for outer walls.

-

Ensure belts are tight and frame is rigid.

-

Tune extrusion temperature for smoother flow.

-

Enable “outer wall before inner wall” in slicer.

Prevention Tips:

-

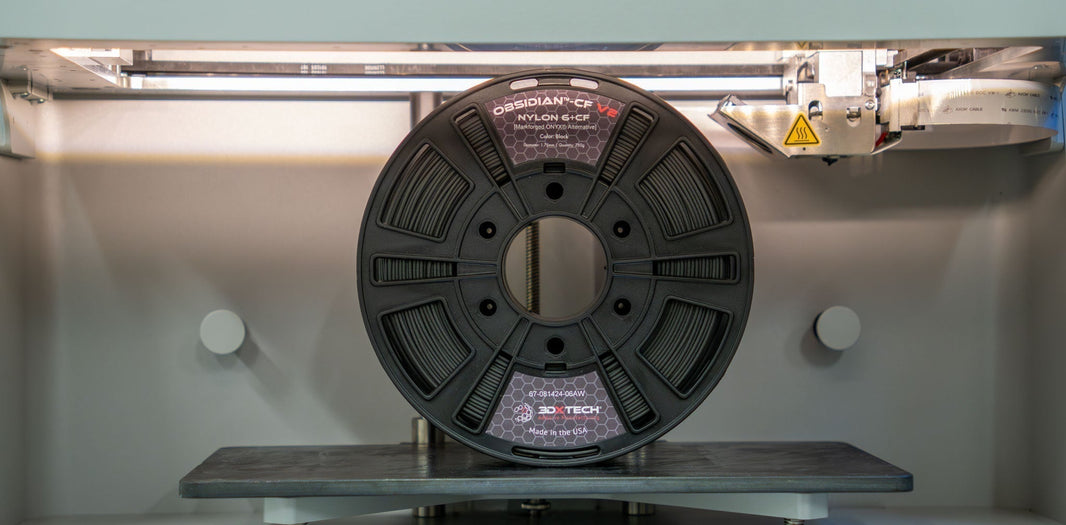

Use consistent, high-quality filament.

-

Perform regular maintenance to prevent mechanical looseness.