CarbonX PETG+CF

$48.00 – $138.00

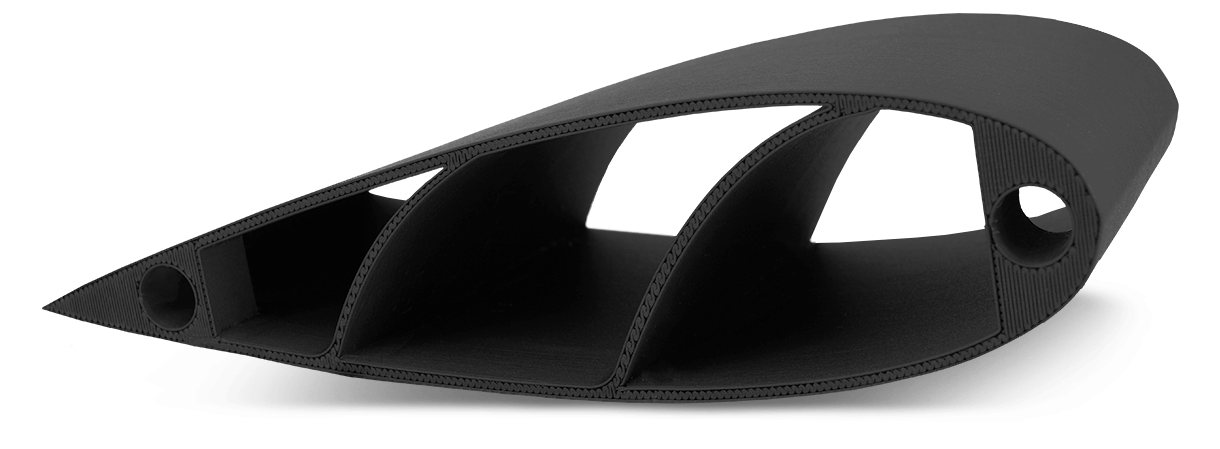

CarbonX™ PETG+CF is made using our high-flow PETG and premium high-modulus carbon fiber. This material offers ease of printing, strength & stiffness, excellent dimensional stability, and an amazing surface finish.

CarbonX™ PETG+CF Carbon Fiber Reinforced Co-Polyester

CarbonX™ PETG+CF is made in the USA using premium PETG and High-Modulus Carbon Fiber (not carbon powder or milled carbon fiber). CarbonX™ PETG+CF is an improved CF reinforced 3D printing filament vs. the competition. This filament is ideal for anyone that desires a structural component with high modulus, excellent surface quality, dimensional stability, light weight, and ease of printing.

Print Recommendations

Extruder Temp

230-260°C

Bed Temp

70-90°C

Heated Chamber

Not required

Nozzle Specs

0.4mm diameter minimum

Hardened Steel Nozzle

Bed Adhesion

Magigoo Bed Prep

Layer Height

0.25mm or higher

Drying Specs

65°C for 4 hours

Supports

Water Soluble Support

Benefits of CarbonX™ PETG+CF Include:

- Superior chemical resistance vs. ABS

- Amorphous structure giving it low, near isotropic shrinkage

- Low moisture absorption, 3x lower than ABS

- Very low odor while printing

- Wide processing range from 230-270°C

Chemical Resistance of PETG:

Unstressed tensile bars molded of PETG exhibit good resistance to dilute aqueous solutions of mineral acids, bases, salts, and soaps, and to aliphatic hydrocarbons, alcohols, and a variety of oils. Halogenated hydrocarbons, short chain length ketones, and aromatic hydrocarbons dissolve or swell the plastic.

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 230-260°C

- Bed Temp: 70-90°C

- Nozzle: We currently recommend a hardened steel nozzle with a minimum diameter of 0.4mm.

- Other: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers smaller than 0.2mm with carbon fiber reinforced filaments.

- Bed Prep: Magigoo Bed Prep Adhesive gives us the best results

- Heated Chamber: Not required

- Supports: Water soluble AquaTek X1 USM works great for complex parts.

- Drying Instructions: 65°C for 4 hours.

Carbon Fiber Reinforced Filament

What Is It?

Fibers 5-10 micrometers wide made of carbon. The fibers are aligned following the axis of the material.

This, along with their physical makeup, are what give this material its excellent properties.

What Does It Do?

Carbon Fibers demonstrate a lot of desirable material properties:

- High stiffness

- High tensile strength

- High heat tolerance

- High chemical resistance

- Low weight

- Low thermal expansion

How Does It Work?

Reinforcing plastic with carbon fibers produces a 3D printing filament which exhibits the best properties of both the carbon fibers and the plastic of choice.

What Is It Good For?

Ideal for any applications which require light weight and rigidity.

Carbon fiber reinforced parts, designed to use less material and save weight, is extremely popular in aerospace, civil engineering, the military, and motorsports.

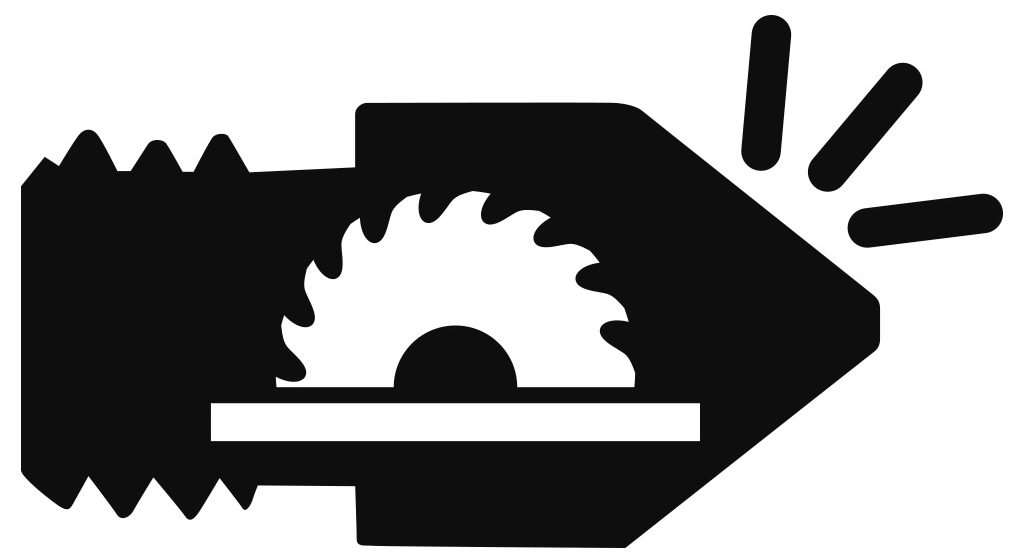

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently and the printer will experience extrusion issues.

Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

What makes CarbonX™ PETG+CF different from standard PETG?

CarbonX™ PETG+CF is enhanced with carbon fiber, which significantly improves its mechanical strength, stiffness, and thermal properties compared to standard PETG. The addition of carbon fiber also reduces the material’s shrinkage during cooling, leading to more dimensionally stable parts that are crucial in precision applications.

How does the addition of carbon fiber enhance the properties of PETG?

The inclusion of carbon fiber in PETG enhances several key properties:

Increased Strength and Stiffness: Carbon fibers are exceptionally strong and stiff, which when embedded in the PETG matrix, increase the overall structural integrity of the material.

Improved Thermal Stability: Carbon fibers have a high thermal tolerance, which helps the composite material withstand higher temperatures without deforming.

Enhanced Durability: The composite material exhibits improved wear and impact resistance, making it suitable for more rugged applications.

In which industries is CarbonX™ PETG+CF most beneficial and why?

CarbonX™ PETG+CF is particularly beneficial in industries where high strength, lightweight, and durable materials are crucial, such as:

Automotive: For manufacturing parts that need to withstand mechanical stress and high temperatures.

Aerospace: For components that require high strength-to-weight ratios and thermal stability.

Consumer Electronics: For creating robust and durable casings and structural components that are also lightweight.

What are the main challenges faced when working with CarbonX™ PETG+CF?

Processing Requirements: CarbonX™ PETG+CF requires specific processing conditions, such as higher extruder temperatures and slower cooling rates, to maintain the integrity of the carbon fibers and the matrix.

Equipment Wear: The abrasive nature of carbon fibers can lead to increased wear and tear on processing equipment, such as extruders and nozzles, requiring more frequent maintenance or the use of specialized equipment.

Cost: While offering superior properties, CarbonX™ PETG+CF can be more expensive than standard PETG, impacting its adoption in cost-sensitive applications.

Can CarbonX™ PETG+CF be recycled, and if so, how?

CarbonX™ PETG+CF can be recycled, though the process is more complex than recycling pure PETG due to the presence of carbon fibers. The material needs to be ground into small particles and then can be used as a filler material for producing new composite materials. Recycling efforts also focus on reclaiming both the PETG and carbon fiber components, although this technology is still developing and not widely available commercially.

Questions?

Send us a message and we'll reach out as soon as we can!