ThermaX TPI [Thermoplastic Polyimide]

$195.00

ThermaX™ TPI 3D Filament is made using Sabic’s EXTEM™ Thermoplastic Polyimide (TPI) and has exceptional mechanical, thermal, and chemical resistance properties. This ultra-polymer is suitable for the most demanding applications in the aerospace, automotive, electronics, and industrial markets.

ThermaX™ TPI 3D Printing Filament, Made Using Sabic EXTEM™ Thermoplastic Polyimide

ThermaX™ TPI is made using Sabic’s Extem™ Thermoplastic Polyimide (TPI) resin. This resin has been formulated specifically for FFF/FDM additive manufacturing. ThermaX™ TPI boasts exceptional thermal properties with a glass transition temperature (Tg) of 247°C and an HDT of 230°C. This material has exceptional mechanical, thermal, and chemical resistance properties and is suitable for the most demanding applications in the aerospace, automotive, electronics, and industrial markets.

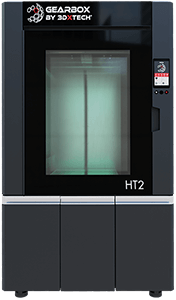

What is TPI? One way to think about our ThermaX™ TPI [Thermoplastic Polyimide] is to consider it a higher-heat version of the venerable Ultem™ 1010 PEI (Polyether Imide). Both TPI and PEI are amorphous thermoplastic polyimides and offer excellent high-heat resistance, strength, and chemical resistance. Where ThermaX™ TPI shines is that it offers superior mechanical properties in applications that are exposed to temperatures above 170°C and up to 230°C (up to 50% higher strength than Ultem™ 1010 at these elevated temperatures). ThermaX™ TPI must be considered a top contender when you need the best performance in the most challenging applications. Our Gearbox™ HT2 printer [HERE] is the ideal platform for printing ThermaX™ TPI and other ultra-polymers.

Gearbox HT2™ 3D Printer: Print industrial-grade parts using our TPI filament and more with the new Gearbox™ HT2 High-Temp 3D Printer.

Print Recommendations

![ThermaX TPI [Thermoplastic Polyimide] Ext Temp 1 Ext Temp 1](https://www.3dxtech.com/wp-content/uploads/2021/01/Ext-Temp-1-1024x1024.jpg)

Extruder Temp 420-445°C

![ThermaX TPI [Thermoplastic Polyimide] Bed Temp Bed Temp](https://www.3dxtech.com/wp-content/uploads/2021/01/Bed-Temp-1024x1024.jpg)

Bed Temp 180-220°C

![ThermaX TPI [Thermoplastic Polyimide] Chamber Temp Chamber Temp](https://www.3dxtech.com/wp-content/uploads/2021/01/Chamber-Temp-1024x1024.jpg)

Heated Chamber Required

![ThermaX TPI [Thermoplastic Polyimide] Nozzle Settings Nozzle Settings](https://www.3dxtech.com/wp-content/uploads/2021/01/Nozzle-Settings-1024x1024.jpg)

Nozzle Specs No special concerns

![ThermaX TPI [Thermoplastic Polyimide] Bed Adhesion Bed Adhesion](https://www.3dxtech.com/wp-content/uploads/2021/01/Bed-Adhesion-1024x1024.jpg)

Bed Adhesion Nano Polymer Adhesive

![ThermaX TPI [Thermoplastic Polyimide] Layer Height Layer Height](https://www.3dxtech.com/wp-content/uploads/2021/01/Layer-Height-1024x1024.jpg)

Layer Height No special concerns

![ThermaX TPI [Thermoplastic Polyimide] Drying Filamen Drying Filamen](https://www.3dxtech.com/wp-content/uploads/2021/01/Drying-Filamen-1024x1024.jpg)

Drying Specs 150°C for 4+ hours

![ThermaX TPI [Thermoplastic Polyimide] Break Away Support Break Away Support](https://www.3dxtech.com/wp-content/uploads/2021/01/Break-Away-Support-1024x1024.jpg)

Supports High Temp Support

Benefits of ThermaX™ TPI Include:

- Exceptional thermal properties: Tg = 247°C, HDT 237°C

- Up to 50% stronger than Ultem™ 1010 at temps above 170°C [170-230°C]

- Superior chemical resistance [auto & aircraft fluids, aliphatic hydrocarbons, alcohols, acids, chlorinated solvents]

- Inherently flame retardant without the use of halogenated additives

- Amorphous polymer with excellent dimensional stability over a wide range of temperatures

- Lower cost than other ultra-polymers such as PEEK and PEKK

Filament Specifications:

1.75mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 420-445°C

- Bed Temp: 180-220°C

- Bed Prep: Nano Polymer Adhesive or 3DXTECH Polyimide Tape gives us the best results

- Heated Chamber: ThermaX™ TPI is going to be difficult to print without using a printer equipped with an actively heated print chamber. Ideally, the chamber temp will be in the 220-240°C range to achieve ideal layer bonding, part strength, and dimensional stability. If your printer cannot reach these chamber temps, then you will want to set it to as high as the printer is capable of reaching (i.e., an 80°C chamber really isn’t going to cut it, but it is better than room temp!). Our Gearbox™ HT2 printer is the ideal platform for printing ThermaX™ TPI and other ultra-polymers.

- Supports: ThermaX HTS High-Temp Support works ideal for complex, high-temp materials just like this.

- Drying Instructions: 150°C for 4+ hours.

ULTEM™ and EXTEM™ are registered trademarks of Sabic Innovative Plastics.3DXTECH manufactures this filament using EXTEM™ TPI resin.3DXTECH™ extrudes ThermaX™ TPI filament using Sabic EXTEM™ resin.Extem AMHH811F

Questions?

Send us a message and we'll reach out as soon as we can!

![ThermaX TPI [Thermoplastic Polyimide] ExtemTPI 175mm Natural 500g ReelPic ExtemTPI 175mm Natural 500g ReelPic](https://www.3dxtech.com/wp-content/uploads/2021/09/ExtemTPI-175mm-Natural-500g-ReelPic.png)

![ThermaX TPI [Thermoplastic Polyimide] ExtemTPI 175mm Natural 500g ReelPic w Part ExtemTPI 175mm Natural 500g ReelPic w Part](https://www.3dxtech.com/wp-content/uploads/2021/09/ExtemTPI-175mm-Natural-500g-ReelPic-w-Part.png)

![ThermaX TPI [Thermoplastic Polyimide] ExtemTPI 175mm Natural 500g ReelPic w Part ExtemTPI 175mm Natural 500g ReelPic w Part](https://www.3dxtech.com/wp-content/uploads/2021/09/ExtemTPI-175mm-Natural-500g-ReelPic-w-Part-300x275.png)