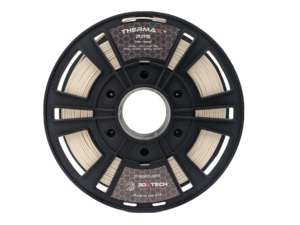

ThermaX PPS [Polyphenylene Sulfide]

$100.00

ThermaX™ PPS [Polyphenylene Sulfide] is widely used in the most demanding applications because it has excellent chemical resistance coupled with superior mechanical and thermal properties.

ThermaX™ PPS 3D Printing Filament

PPS (Polyphenylene Sulfide) is a high-performance polymer that exhibits exceptional chemical resistance along with high thermal and mechanical properties. Widely known as one of the most chemically resistant thermoplastic materials available.

PPS is completely insoluble in any known solvent under 200°C.

PPS is used in some of the most demanding applications in Auto, Chemical Processing, Oil & Gas, and Electronics. It is inherently flame retardant and self extinguishing, making it an ideal material for electrical / electronics applications.

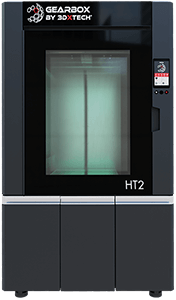

Gearbox HT2™ 3D Printer: Print industrial-grade parts using our PPS filament and more with the new Gearbox™ HT2 High-Temp 3D Printer.

Print Recommendations

![ThermaX PPS [Polyphenylene Sulfide] Ext Temp 1 Ext Temp 1](https://www.3dxtech.com/wp-content/uploads/2021/01/Ext-Temp-1-1024x1024.jpg)

Extruder Temp

315-345°C

![ThermaX PPS [Polyphenylene Sulfide] Bed Temp Bed Temp](https://www.3dxtech.com/wp-content/uploads/2021/01/Bed-Temp-1024x1024.jpg)

Bed Temp

120-160°C

![ThermaX PPS [Polyphenylene Sulfide] Chamber Temp Chamber Temp](https://www.3dxtech.com/wp-content/uploads/2021/01/Chamber-Temp-1024x1024.jpg)

Heated Chamber

60-90°C

![ThermaX PPS [Polyphenylene Sulfide] Nozzle Settings Nozzle Settings](https://www.3dxtech.com/wp-content/uploads/2021/01/Nozzle-Settings-1024x1024.jpg)

Nozzle Specs

No special concerns

![ThermaX PPS [Polyphenylene Sulfide] Bed Adhesion Bed Adhesion](https://www.3dxtech.com/wp-content/uploads/2021/01/Bed-Adhesion-1024x1024.jpg)

Bed Adhesion

Nano Polymer Adhesive

![ThermaX PPS [Polyphenylene Sulfide] Layer Height Layer Height](https://www.3dxtech.com/wp-content/uploads/2021/01/Layer-Height-1024x1024.jpg)

Layer Height

No special concerns

![ThermaX PPS [Polyphenylene Sulfide] Drying Filamen Drying Filamen](https://www.3dxtech.com/wp-content/uploads/2021/01/Drying-Filamen-1024x1024.jpg)

Drying Specs

110°C for 4 hours

![ThermaX PPS [Polyphenylene Sulfide] Break Away Support Break Away Support](https://www.3dxtech.com/wp-content/uploads/2021/01/Break-Away-Support-1024x1024.jpg)

Supports

HTS

Benefits of ThermaX™ PPS:

- Melting temperatures (Tm) of 285°C

- Glass Transition temperature (Tg) of 85°C

- Excellent chemical resistance, insoluble in ANY known solvent under 200°C

- Stable dielectric constant and dissipation factor over a wide range of temps and frequencies.

- Inherently flame resistant and self-extinguishing

- Long-term hydrolytic stability for very low moisture absorption

- Exceptional strength and modulus even at elevated temperatures

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 315-345°C

- Bed Temp: 120-160°C

- Bed Prep: Nano Polymer Adhesive and 3DXTECH Polyimide Tape work best for us.

- Heated Chamber: Recommended, up to 50-90°C if available on your printer

- Supports: ThermaX™ HTS High-Temp Support is designed specifically to work with high-temp materials like this one.

- Other: No cooling fan and print speeds of 16 mm/s as a starting point.

- Drying Instructions: 110°C for 4 hours.

Annealing (Post-Crystalizing) 3D Printed PPS Parts:

Parts printed with PPS must be annealed after printing to ramp-up the crystallinity in the resin. This will maximize mechanical, thermal, and chemical resistance properties. Full annealing generally requires 2-4 hours of heating at 130°C. The following process for annealing your ThermaX™ PPS parts will help assure ideal performance.

- Place printed parts in cool, room-temp oven. Supports may be left on the part if there is a risk of part warping without them.

- Set temp to 80°C and allow to stabilize for 1 hour.

- Raise oven temperature to 130°C and allow to stabilize 2-3 hours, longer depending upon the size/thickness of the part.

- Turn off oven heat and allow the printed part to cool to room temperature.

Questions?

Send us a message and we'll reach out as soon as we can!

![ThermaX PPS [Polyphenylene Sulfide] pps natural 500 Sample of natural PPS (Polyphenylene Sulfide) 3D printer filament](https://www.3dxtech.com/wp-content/uploads/2022/10/pps_natural_500.png)

![ThermaX PPS [Polyphenylene Sulfide] PPS Tstat housing 2 96879 PPS Tstat housing 2 96879](https://www.3dxtech.com/wp-content/uploads/2021/01/PPS-Tstat-housing-2__96879.jpg)

![ThermaX PPS [Polyphenylene Sulfide] PPS Tstat housing 2 96879 PPS Tstat housing 2 96879](https://www.3dxtech.com/wp-content/uploads/2021/01/PPS-Tstat-housing-2__96879-300x359.jpg)