CarbonX PA6+CF Gen 3

$48.00 – $210.00

CarbonX™ PA6+CF [Gen3] is made using a specialty Nylon 6 [PA6] copolymer and high-modulus carbon fiber. This is the go-to material for industrial applications that require superior thermal, mechanical, and chemical resistance properties while retaining the ease of printing that you’ve come to expect.

Gen 3 CarbonX™ PA6+CF Carbon Fiber Reinforced Nylon

Gen 3 CarbonX™ PA6+CF filament is formulated using a PA6 copolymer reinforced with high-modulus carbon fiber. This filament is ideal for anyone that desires a structural component with high modulus, improved chemical and thermal resistance, excellent surface quality, and ease of printing. Gen3 has higher HDT than our previous grades (147°C at .45MPa) allowing for expanded use in higher-temp applications.

Unparalleled rigidity gives designers the properties they need to make their 3D printed parts with less material and save weight without sacrificing stiffness.

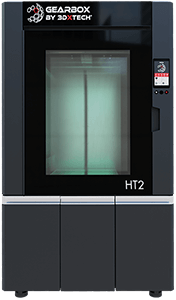

Gearbox HT2™ 3D Printer: Print industrial-grade parts using our PA6+CF and more with the new Gearbox™ HT2 High-Temp 3D Printer.

Print Recommendations

Extruder Temp

240-270°C

Bed Temp

80-110°C

Heated Chamber

Not required, but

improves layer bonding

Nozzle Specs

0.4mm diameter minimum

Hardened Steel Nozzle

Bed Adhesion

Magigoo Bed Prep

Layer Height

0.25mm or higher

Drying Specs

90°C for 4 hours

Supports

Water Soluble Support

Benefits of Nylon PA6+CF:

- Excellent printability

- High tensile strength and rigidity

- Abrasion and wear resistance

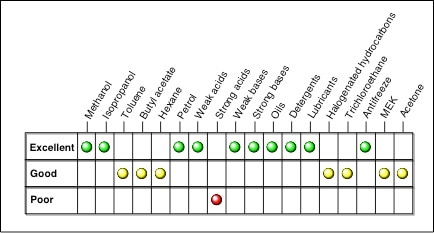

- Improved chemical resistance over traditional 3D printing materials

- High thermal properties

Filament Specifications:

1.75mm and 2.85mm +/- 0.05mm in diameter

Recommended Print Settings:

- Extruder: 240-270°C

- Bed Temp: 80-110°C

- Nozzle: We currently recommend a hardened steel nozzle with a minimum diameter of 0.4mm

- Other: Ideal layer height is 60% of nozzle diameter. We do not recommend printing layers smaller than 0.2mm with carbon fiber reinforced filaments.

- Bed Prep: Magigoo Bed Prep Adhesive gives us the best results

- Heated Chamber: Not required, but a heated chamber between 30-80°C allows for superior layer bonding and mechanical properties

- Supports: Water soluble AquaTek X1 USM works great for complex parts.

- Drying Instructions: 90°C for 4 hours.

Carbon Fiber Reinforced Filament

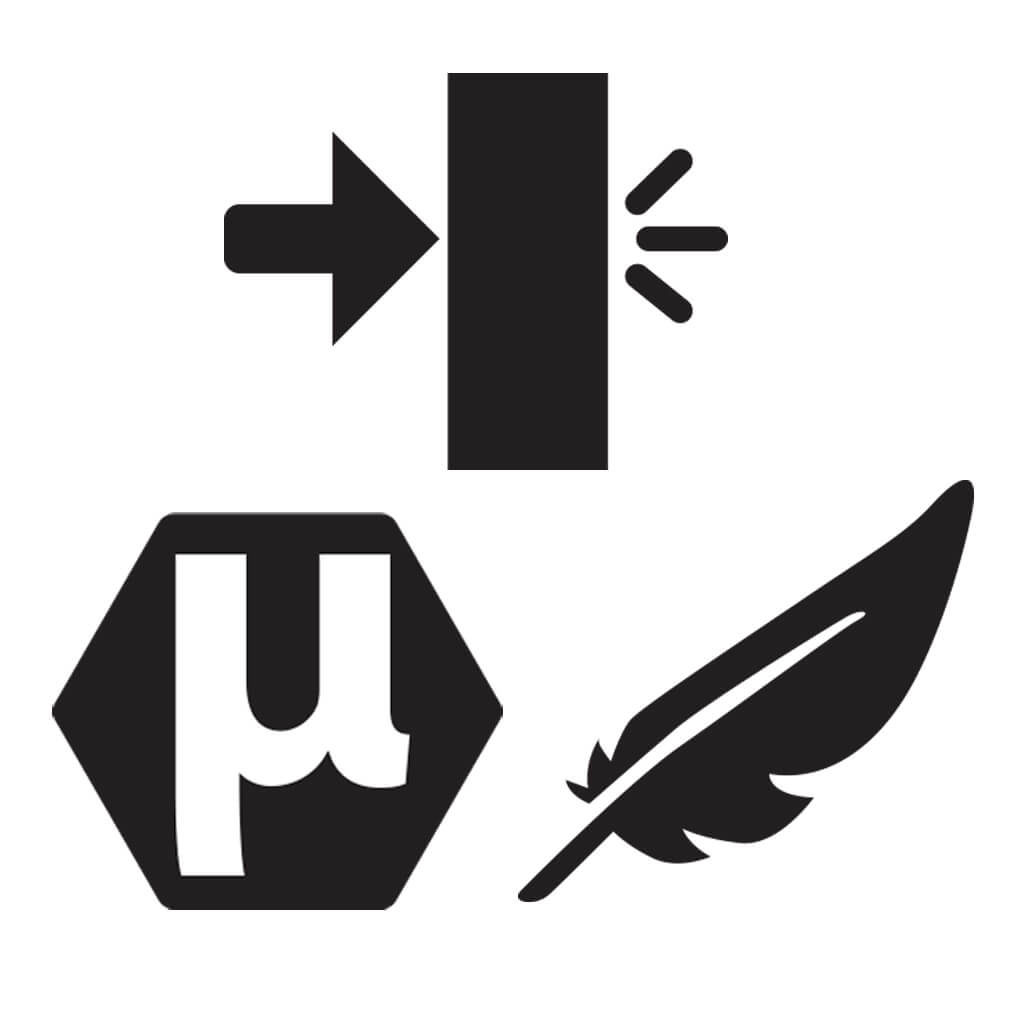

What Is It?

Fibers 5-10 micrometers wide made of carbon. The fibers are aligned following the axis of the material.

This, along with their physical makeup, are what give this material its excellent properties.

What Does It Do?

Carbon Fibers demonstrate a lot of desirable material properties:

- High stiffness

- High tensile strength

- High heat tolerance

- High chemical resistance

- Low weight

- Low thermal expansion

How Does It Work?

Reinforcing plastic with carbon fibers produces a 3D printing filament which exhibits the best properties of both the carbon fibers and the plastic of choice.

What Is It Good For?

Ideal for any applications which require light weight and rigidity.

Carbon fiber reinforced parts, designed to use less material and save weight, is extremely popular in aerospace, civil engineering, the military, and motorsports.

Abrasive Material

This material is particularly abrasive among 3D printing filaments. Users may find standard brass nozzles are chewed through very quickly compared to standard wear and tear. When worn through, the nozzle diameter will widen inconsistently and the printer will experience extrusion issues.

Because of this, it's strongly recommended this material be printed through a hardened steel nozzle rather than a softer metal. Hardened steel nozzles can often be inexpensive and easily installed depending on your printer manufacturer's instructions.

What is Gen 3 CarbonX™ PA6+CF?

Gen 3 CarbonX™ PA6+CF is a high-performance composite material made by reinforcing polyamide 6 (PA6) nylon with carbon fibers. This enhancement significantly improves its mechanical properties, thermal stability, and durability, making it ideal for demanding engineering applications.

How does carbon fiber reinforcement improve the properties of PA6 nylon?

Carbon fiber reinforcement increases the tensile strength, stiffness, and thermal stability of PA6 nylon. It also improves wear resistance and reduces the material’s overall weight. These enhancements make the nylon composite more suitable for applications that experience high mechanical loads and extreme temperatures.

What are the primary applications of Gen 3 CarbonX™ PA6+CF?

Primary applications include automotive components, aerospace parts, industrial machinery, and high-performance consumer goods. The material is particularly favored in areas where a combination of strength, thermal stability, and light weight is crucial.

What are the advantages of using Gen 3 CarbonX™ PA6+CF over other composite materials?

Gen 3 CarbonX™ PA6+CF offers superior mechanical strength and thermal properties compared to many other composite materials. It also provides better dimensional stability, resistance to chemicals, and durability, which are essential for long-lasting, reliable components in harsh environments.

Can Gen 3 CarbonX™ PA6+CF be recycled?

Yes, although recycling carbon fiber-reinforced materials can be challenging due to the embedded carbon fibers. However, specialized recycling processes can reclaim both the nylon and carbon fiber for use in new composite materials or as fillers in other products.

Is Gen 3 CarbonX™ PA6+CF environmentally sustainable?

While the recycling process for carbon fiber composites is complex, efforts are ongoing to improve the sustainability of these materials. Using Gen 3 CarbonX™ PA6+CF can also lead to products that last longer and perform better, reducing waste and the frequency of replacements.

Questions?

Send us a message and we'll reach out as soon as we can!

![CarbonX HTN+CF [High Temp Nylon + Carbon Fiber] 495 CF HTN 175mm Black 500g 3D Printer Filament HTN+CF High Temp CF Nylon 1.75mm Black 500g 3D Printer Filament](https://www.3dxtech.com/wp-content/uploads/2021/01/495-CF-HTN-175mm-Black-500g-3D-Printer-Filament-100x100.png)